Descriptio Producti

Tubus ferreus inconsutilis est tubus vel tubi ferrei sine sutura vel iunctura sudata. Tubi ferrei carbonis inconsutilis ex lingotibus ferreis vel solidis tubis fragmentis, quae in tubos capillares perforantur, deinde per laminationem calidam, laminationem frigidam vel extractionem frigidam fiunt, cum commodis excellentis durabilitatis et resistentiae corrosionis.

Tubus chalybis carbonis sine suturis est cylindrus sectionis tubularis vel cava, plerumque late adhibitus ad liquores et gases (fluidos), pulveres et alia similia solida parva transportanda vel transferenda.

Womic tubos ferreos sine suturis praebet ad opera constructionis terrestris/extra litus, inter quos tubos sine suturis calido laminatos et tubos sine suturis frigido tractos (laminatos).

Specificationes

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| API 5CT: J55, K55, N80, L80, P110 |

| API 5D: E75, X95, G105, S135 |

| EN10210 :S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A106: GR.A, GR.B, GR.C |

| ASTM A53/A53M: GR.A, GR.B |

| ASTM A335: P1, P2, 95, P9, P11, P22, P23, P91, P92, P122 |

| ASTM A333: Gradus 1, Gradus 3, Gradus 4, Gradus 6, Gradus 7, Gradus 8, Gradus 9, Gradus 10, Gradus 11 |

| DIN 2391: St30Al, St30Si, St35, St45, St52 |

| DIN EN 10216-1 : P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| JIS G3454: STPG 370, STPG 410 |

| JIS G3456: STPT 370, STPT 410, STPT 480 |

| GB/T 8163: 10#, 20#, Q345 |

| GB/T 8162: 10#, 20#, 35#, 45#, Q345 |

Norma et Gradus

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 | Tubus chalybis carbonis sine sutura ad tubos lineares, petroleum, industrias gasi naturalis, systemata translationis per fistulas. |

| API 5CT: J55, K55, N80, L80, P110 | Tubus chalybis carbonis sine sutura ad involucrum et tubos olei et gasi. |

| API 5D: E75, X95, G105, S135 | Tubi terebrantes, tubi perforantes ad oleum et gas. |

| EN10210 :S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H | Tubus chalybis carbonis sine suturis ad inceptum constructionis. |

| ASTM A106: GR.A, GR.B, GR.C | Tubus chalybis carbonis sine suturis ad inceptum constructionis. |

| ASTM A53/A53M: GR.A, GR.B | Tubus chalybis carbonis sine suturis ad inceptum constructionis. |

| ASTM A335: P1, P2, 95, P9, P11, P22, P23, P91, P92, P122 | Tubus chalybis carbonis sine suturis ad altas temperaturas industriae servitii. |

| ASTM A333: Gradus 1, Gradus 3, Gradus 4, Gradus 6, Gradus 7, Gradus 8, Gradus 9, Gradus 10, Gradus 11 | Tubus chalybis carbonis sine suturis ad industriam temperaturarum humilium. |

| DIN 2391: St30Al, St30Si, St35, St45, St52 | Tubus praevisionis sine suturis carbonis frigide tractus |

| DIN EN 10216-1 : P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 | Tubi circulares chalybis non mixti sine suturis, requisitis specialibus obnoxii |

| GB/T 8163: 10#, 20#, Q345 | Tubus chalybis carbonis sine sutura ad usum communem. |

| GB/T 8162: 10#, 20#, 35#, 45#, Q345 | Tubus chalybis carbonis sine sutura ad usum communem. |

Qualitatis Moderatio

Inspectio Materiae Rudis, Analysis Chemica, Examen Mechanica, Inspectio Visualis, Examen Tensionis, Examen Dimensionis, Examen Flexionis, Examen Planificationis, Examen Impactus, Examen DWT, Examen NDT, Examen Hydrostaticum, Examen Duritudinis etc....

Notatio, pictura ante traditionem.

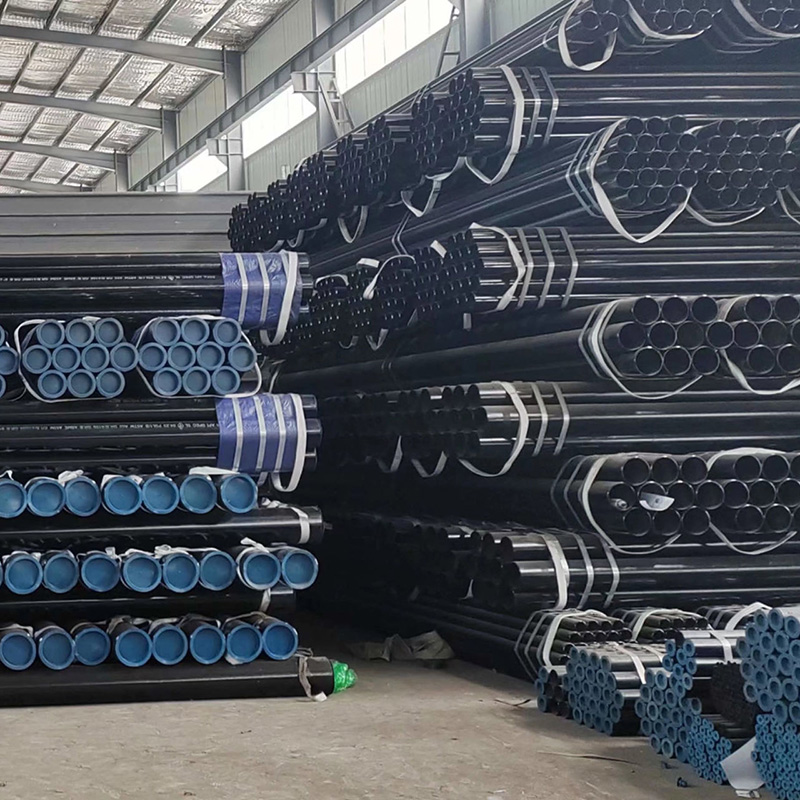

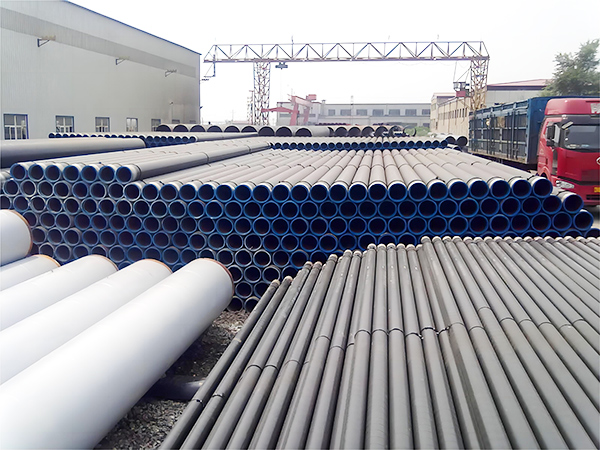

Sarcina et Transportatio

Modus sarcinandi tuborum ferreorum purgationem, congregationem, involucrum, fasciculationem, firmationem, inscriptionem, palettationem (si opus est), receptacula, reponendum, obsignationem, transportationem, et disarcionem complectitur. Genera varia tuborum ferreorum et iuncturae cum variis modis sarcinandi. Hic processus comprehensivus efficit ut tubi ferrei transportentur et ad destinationem suam in optima condicione perveniant, ad usum destinatum parati.

Usus et Applicatio

Tubi ferrei quasi spina dorsalis modernae artis industrialis et civilis funguntur, amplam varietatem applicationum sustinentes quae ad progressionem societatum et oeconomiarum toto orbe conferunt.

Tubi et accessiones ferreae, quas Womic Steel producimus, late adhibitae sunt ad fistulas petrolei, gasii, cibustibilis et aquae, opera extra litus/terra, portuum maritimorum constructionis et aedificationis, dragationem, ferrum structurale, palos et pontium constructionis, necnon tubos ferreos accurati ad productionem cylindrorum transportatorum, et cetera...