Descriptio Producti

Specificationes tuborum ferreorum caldariorum cum dimensionibus totalibus (velut diametro vel longitudine) et crassitudine parietis, tubi ferrei caldariorum in fistulis, apparatu technologiae thermalis, machinis industrialibus, exploratione geologica petrolei, vasis, industria chemica, et aliis usibus specialibus adhiberi possunt.

Tubi/fistulae ferreae pro caldariis ex tubis sine suturis fabricantur, sive ex chalybe carbonico sive ex chalybe mixto. Tubi/fistulae pro caldariis late in caldariis vaporariis, permutatoribus caloris, productione energiae, officinis combustibilium fossilium, officinis processuum industrialium, officinis electricis, molis sacchari productionis, etc. adhibentur. Tubi vel fistulae pro caldariis saepe ut tubi pro caldariis mediae pressionis vel altae pressionis adhibentur.

Specificationes

| ASTM A179 |

| ASTM A192 |

| ASTM A209: Gr. T1, Gr. T1a, Gr. T1b |

| ASTM A210:Gr.A1, Gr.C |

| ASTM A106: Gradus A, Gradus B, Gradus C |

| DIN 17175: ST35.8, ST45.8, 15Mo3, 13CrMo44 |

| EN 10216-2: P235GH, P265GH, 16Mo3, 10CrMo5-5, 13CrMo4-5 |

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| ASTM A178:Gr.A, Gr.C |

| ASTM A335: P1, P2, 95, P9, P11, P22, P23, P91, P92, P122 |

| ASTM A333: Gradus 1, Gradus 3, Gradus 4, Gradus 6, Gradus 7, Gradus 8, Gradus 9, Gradus 10, Gradus 11 |

| ASTM A312/A312M:304, 304L, 310/S, 310H, 316, 316L, 321, 321H et cetera... |

| ASTM A269/A269M:304, 304L, 310/S, 310H, 316, 316L, 321, 321H etc... |

| EN 10216-5:1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4432, 1.4435, 1.4541, 1.4550. |

Norma et Gradus

Tubi Caldarii StandardGradus:

ASME SA-179M, ASME SA-106, ASTM A178, ASME SA-192M, EN10216-1, JIS G3461, ASME SA-213M, DIN17175, DIN1629.

Status traditionis: Recoctum, normalizatum, temperatum, superficie oleatum, nigro colore pictum, sabbia perforatum, galvanizatum in calido.

| ASME SA-179M: | Tubi Permutatoris Caloris et Condensatoris ex Chalybe Carbonis Humilis, Frigido Tracti, Sinus Suturibus. |

| ASME SA-106: | Tubus Chalybis Carbonis ad Servitium Altae Temperaturae. |

| ASTM A178: | Tubi Caldariorum et Supercalefactorum ex Chalybe Carbonario et Chalybe Carbonario-Manganeso Conglutinati Resistentia Electrica. |

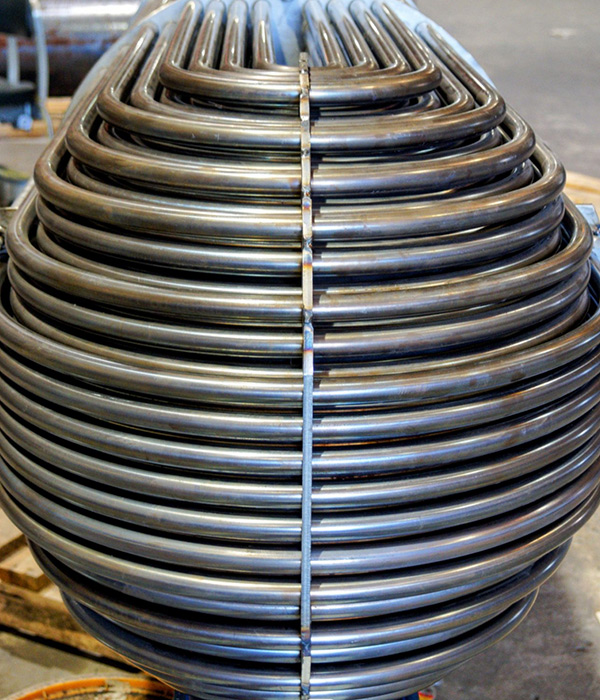

| ASME SA-192M: | Tubi Caldariorum ex Chalybe Carbonico Sinuosis ad Machinas Altae Pressionis. |

| ASME SA-210M: | Tubi Caldariorum et Supercalefactorum ex Chalybe Carbonis Medio Sinuosae. |

| EN10216-1/2: | Tubi ex chalybe non mixto, sine suturis, ad usus pressorios, cum proprietatibus specificatis temperaturae ambiente. |

| JIS G3454: | Tubi chalybis carbonis ad usum pressionis sub temperatura maxima circiter 350 graduum Celsii |

| JIS G3461: | Tubi Chalybis Carbonis pro Caldario et Permutatore Caloris. |

| GB 5310: | Tubi et fistulae chalybeae sine suturis pro caldariis altae pressionis. |

| ASME SA-335M: | Caldarium, supercalefactor et tubus permutatoris caloris ex chalybe ferritico et austenitico mixto sine suturis. |

| ASME SA-213M: | Tubi ex chalybe mixto pro caldariis, supercalefactoribus et permutatoribus caloris. |

| DIN 17175: | Tubi Chalybei Sinsaturae ad Industriam Caldariorum, tubi chalybei sine sutura calori resistentes, ad fistulas industriae caldariorum adhibiti. |

| DIN 1629: | Caldariae nimium calefactae, fistulae fabricationis, vasa, apparatus, aptationes tuborum, et ut permutatores caloris per fistulas austeniticas. |

Qualitatis Moderatio

Inspectio Materiae Rudis, Analysis Chemica, Examen Mechanica, Inspectio Visualis, Examen Tensionis, Examen Dimensionis, Examen Flexionis, Examen Planificationis, Examen Impactus, Examen DWT, Examen NDT, Examen Hydrostaticum, Examen Duritudinis…..

Notatio, pictura ante traditionem.

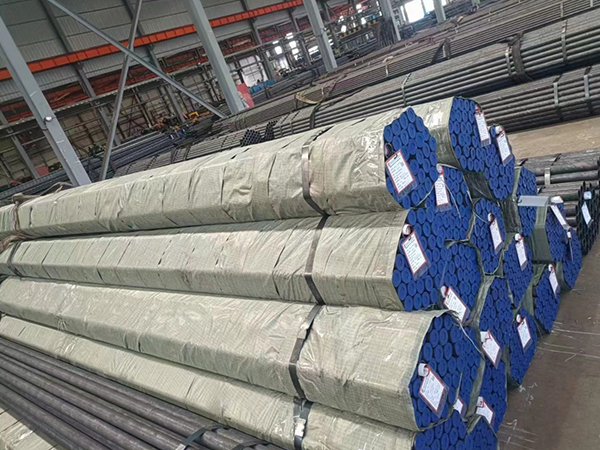

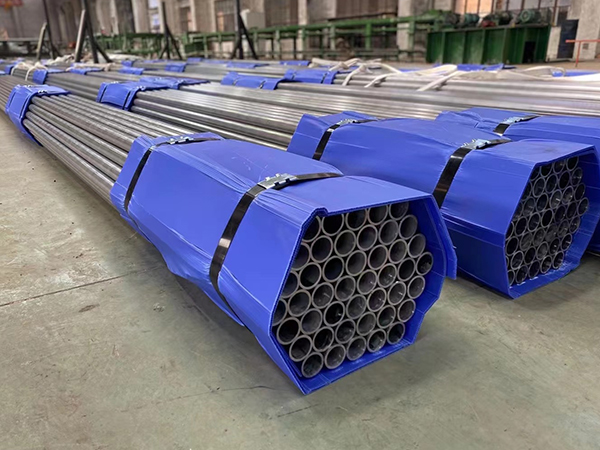

Sarcina et Transportatio

Modus sarcinandi tuborum ferreorum purgationem, congregationem, involucrum, fasciculationem, firmationem, inscriptionem, palettationem (si opus est), receptacula, reponendum, obsignationem, transportationem, et disarcionem complectitur. Genera varia tuborum ferreorum et iuncturae cum variis modis sarcinandi. Hic processus comprehensivus efficit ut tubi ferrei transportentur et ad destinationem suam in optima condicione perveniant, ad usum destinatum parati.

Usus et Applicatio

Tubi ferrei quasi spina dorsalis modernae artis industrialis et civilis funguntur, amplam varietatem applicationum sustinentes quae ad progressionem societatum et oeconomiarum toto orbe conferunt.

Tubi et accessiones ferreae, quas Womic Steel producimus, late adhibitae sunt ad fistulas petrolei, gasii, cibustibilis et aquae, opera extra litus/terra, portuum maritimorum constructionis et aedificationis, dragationem, ferrum structurale, palos et pontium constructionis, necnon tubos ferreos accurati ad productionem cylindrorum transportatorum, et cetera...