Descriptio Producti

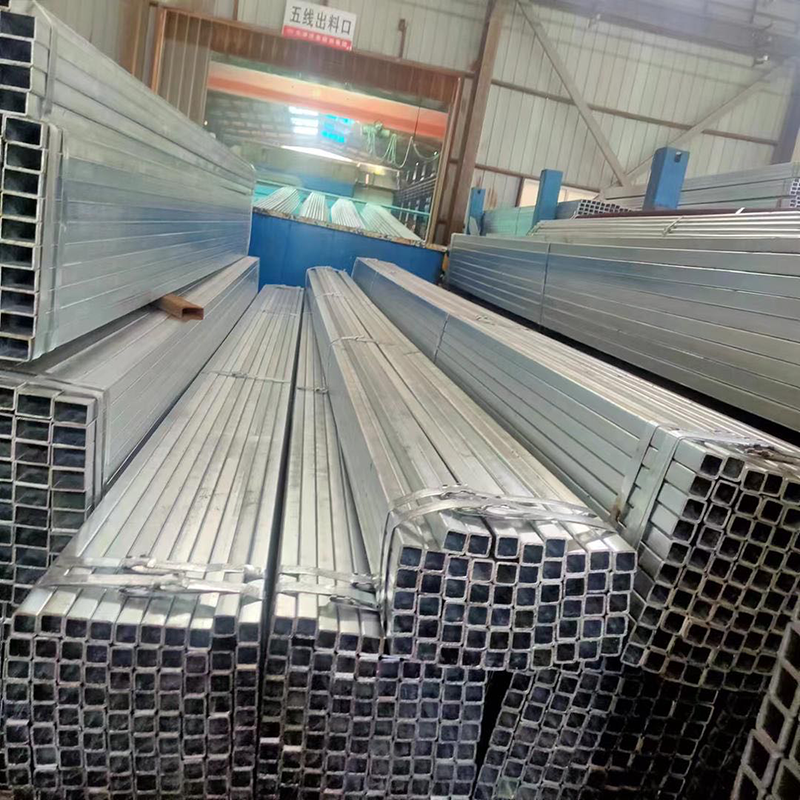

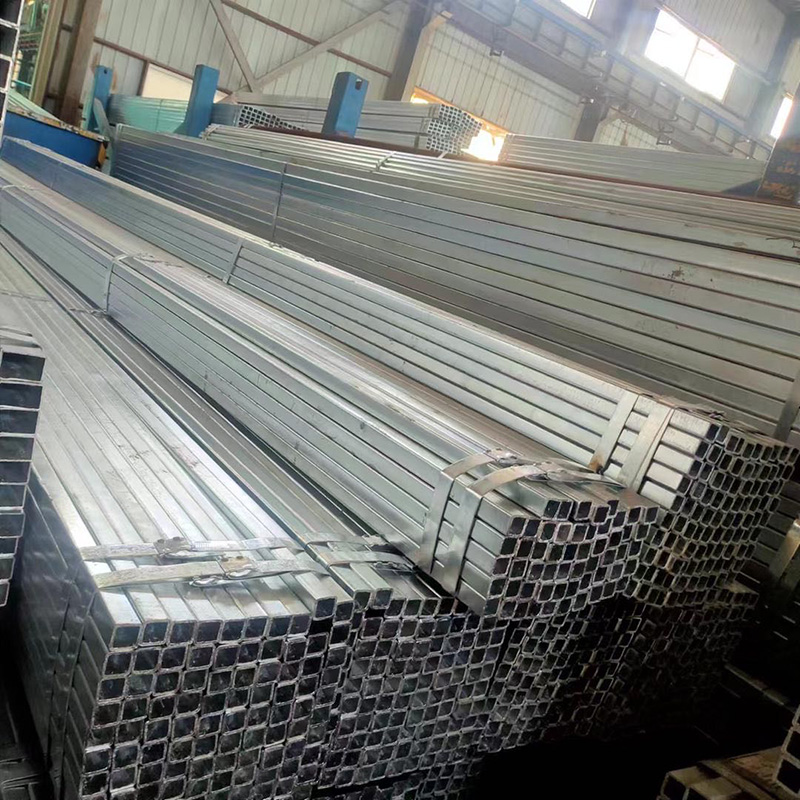

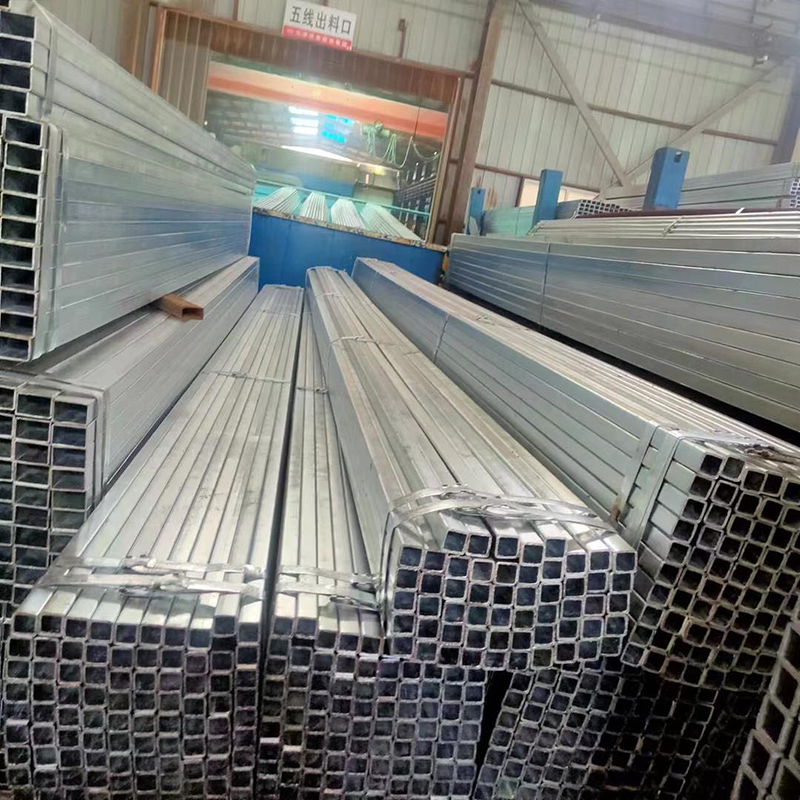

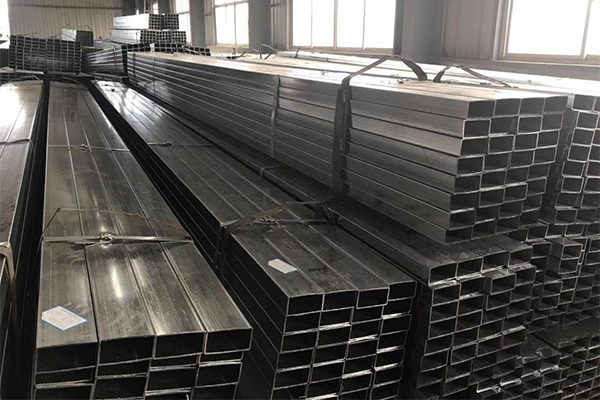

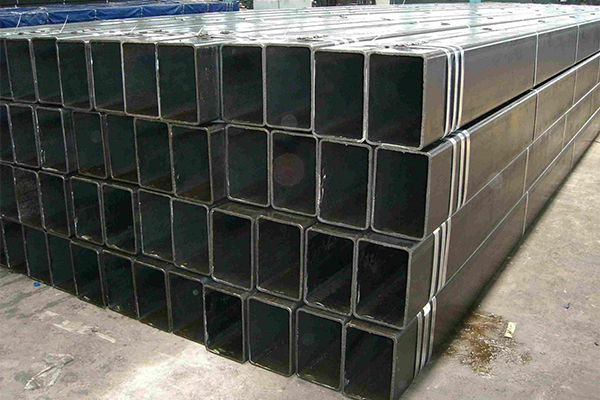

Tubi quadrati et rectangulares sunt tubi extrusi qui late adhibentur ad omnia genera operum fabricationis ubi levitas et resistentia corrosionis cura primaria sunt. Tubus quadratus angulos quadratos intus et extra habet, sine sutura suturae.

Tubi quadrati et rectangulares sunt materiae aedificatoriae versatiles, durabiles, et sumptibus parcissimae, in constructione, industria, supellectili, et applicationibus decorativis adhibitae. Womic Steel amplam seriem tuborum quadratorum ferreorum variis magnitudinibus et crassitudinibus offert.

Sectiones cavae rectangulares/quadratae ex spiralibus formantur et deinde per seriem matricum ducuntur. Ab intus conglutinantur ut formam suam forment.

Processus sectionis cavae (tubuli quadrati/rectangulares):

● Sectio Cava Quadrata Frigida Formata

● Sectio Cava Rectangularis Frigida Formata

● Sectio Cava Quadrata Calida Finita

● Sectio Cava Rectangularis Calida Finita

Classificatio Processus Productionis Tubi Ferrei Quadrati

Secundum processum productionis, tubus quadratus dividitur in: tubulum quadratum sine suturis calido laminatum, tubulum quadratum sine suturis frigido tractum, tubulum quadratum extrusum sine dimensione, tubulum quadratum sudatum.

Tubus quadratus/rectangulatus sudatus dividitur in:

(a) secundum processum tubi quadrati arcu sudati, tubi quadrati resistentia sudati (alta frequentia, humilis frequentia), tubi quadrati gaso sudati, tubi quadrati fornace sudati.

(b) secundum suturam tubi quadrati recti suturi, tubi quadrati spiraliter suturi.

Specificationes

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| API 5CT: J55, K55, N80, L80, P110 |

| ASTM A252: GR.1, GR.2, GR.3 |

| EN 10219-1: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A53/A53M: GR.A, GR.B |

| BS 1387: Classis A, Classis B |

| ASTM A135/A135M: GR.A, GR.B |

| EN 10217: P195TR1 / P195TR2, P235TR1 / P235TR2, P265TR1 / P265TR2 |

| DIN 2458: St37.0, St44.0, St52.0 |

| AS/NZS 1163: Gradus C250, Gradus C350, Gradus C450 |

| SANS 657-3: 2015 |

| Magnitudines productionis tuborum/tuborum ferreorum quadratorum: Diameter externus: 16*16mm ~ 1000*1000mm Crassitudo parietis: 0.4mm ~ 50mm | |

| Magnitudines per MM (diametrum) | Crassitudo |

| mm | mm |

| 16mm × 16mm | 0.4mm ~ 1.5mm |

| 18mm × 18mm | 0.4mm ~ 1.5mm |

| 20mm × 20mm | 0.4mm ~ 3mm |

| 22mm × 22mm | 0.4mm ~ 3mm |

| 25mm × 25mm | 0.6mm ~ 3mm |

| 30mm × 30mm | 0.6mm ~ 4mm |

| 32mm × 32mm | 0.6mm ~ 4mm |

| 34mm × 34mm | 1mm ~ 2mm |

| 35mm × 35mm | 1mm ~ 4mm |

| 38mm × 38mm | 1mm ~ 4mm |

| 40mm × 40mm | 1mm ~ 4.5mm |

| 44mm × 44mm | 1mm ~ 4.5mm |

| 45mm × 45mm | 1mm ~ 5mm |

| 50mm × 50mm | 1mm ~ 5mm |

| 52mm × 52mm | 1mm ~ 5mm |

| 60mm × 60mm | 1mm ~ 5mm |

| 70mm × 70mm | 2mm ~ 6mm |

| 75mm × 75mm | 2mm ~ 6mm |

| 76mm × 76mm | 2mm ~ 6mm |

| 80mm × 80mm | 2mm ~ 8mm |

| 85mm × 85mm | 2mm ~ 8mm |

| 90mm × 90mm | 2mm ~ 8mm |

| 95mm × 95mm | 2mm ~ 8mm |

| 100mm × 100mm | 2mm ~ 8mm |

| 120mm × 120mm | 4mm ~ 8mm |

| 125mm × 125mm | 4mm ~ 8mm |

| 130mm × 130mm | 4mm ~ 8mm |

| 140mm × 140mm | 6mm ~ 10mm |

| 150mm × 150mm | 6mm ~ 10mm |

| 160mm × 160mm | 6mm ~ 10mm |

| 180mm × 180mm | 6mm ~ 12mm |

| 200mm × 200mm | 6mm ~ 30mm |

| 220mm × 220mm | 6mm ~ 30mm |

| 250mm × 250mm | 6mm ~ 30mm |

| 270mm × 270mm | 6mm ~ 30mm |

| 280mm × 280mm | 6mm ~ 30mm |

| 300mm × 300mm | 8mm ~ 30mm |

| 320mm × 320mm | 8mm ~ 30mm |

| 350mm × 350mm | 8mm ~ 30mm |

| 380mm × 380mm | 8mm ~ 30mm |

| 400mm × 400mm | 8mm ~ 30mm |

| 420mm × 420mm | 10mm ~ 30mm |

| 450mm × 450mm | 10mm ~ 30mm |

| 480mm × 480mm | 10mm ~ 30mm |

| 500mm × 500mm | 10mm ~ 30mm |

| 550mm × 550mm | 10mm ~ 40mm |

| 600mm × 600mm | 10mm ~ 40mm |

| 700mm × 700mm | 10mm ~ 40mm |

| 800mm × 800mm | 10mm ~ 50mm |

| 900mm × 900mm | 10mm ~ 50mm |

| 1000mm × 1000mm | 10mm ~ 50mm |

| Magnitudines productionis tuborum/tuborum ferreorum rectangularium: Diameter externus: 40*20mm ~ 300*200mm Crassitudo parietis: 1.6mm ~ 16mm | ||||||

| MAGNITUDO mm | PONDUS kg/m | AESTIMATA LIBRAS PER PEDEM | MAGNITUDO mm | PONDUS kg/m | ||

| AESTIMATA LIBRAS PER PEDEM | ||||||

| 40 × 20 × 1.60 | 1.38 | 0.93 | 150 × 100 × 6.30 | 22.4 | 15.08 | |

| 40 × 20 × 2.60 | 2.1 | 1.41 | 150 × 100 × 8.00 | 27.7 | 18.64 | |

| 50 × 30 × 1.60 | 1.88 | 1.27 | 150 × 100 × 10.00 | 35.714 | XXIV.IV | |

| 50 × 30 × 2.60 | 2.92 | 1.97 | 160 × 80 × 3.20 | 11.5 | 7.74 | |

| 50 × 30 × 2.90 | 3.32 | 2.23 | 160 × 80 × 4.00 | 14.3 | 9.62 | |

| 50 × 30 × 3.20 | 3.49 | 2.35 | 160 × 80 × 5.00 | 17.4 | 11.71 | |

| 50 × 30 × 4.00 | 4.41 | 2.97 | 160 × 80 × 6.30 | 21.4 | 14.4 | |

| 60 × 40 × 2.60 | 3.73 | 2.51 | 160 × 80 × 8.00 | 26.4 | 17.77 | |

| 60 × 40 × 2.90 | 4.23 | 2.85 | 160 × 80 × 10.00 | 32.545 | 21.87 | |

| 60 × 40 × 3.20 | 4.5 | 3.03 | 160 × 90 × 4.50 | 16.6 | 11.17 | |

| 60 × 40 × 4.00 | 5.67 | 3.82 | 160 × 90 × 5.60 | 20.4 | 13.73 | |

| 70 × 40 × 2.90 | 4.69 | 3.16 | 160 × 90 × 7.10 | 25.3 | 17.03 | |

| 70 × 40 × 4.00 | 6.3 | 4.24 | 160 × 90 × 8.80 | 30.5 | 20.53 | |

| 80 × 40 × 2.60 | 4.55 | 3.06 | 160 × 90 × 10.00 | 34.1 | 22.95 | |

| 80 × 40 × 2.90 | 5.14 | 3.46 | 180 × 100 × 4.00 | 16.8 | 11.31 | |

| 80 × 40 × 3.20 | 5.5 | 3.7 | 180 × 100 × 5.00 | 20.5 | 13.8 | |

| 80 × 40 × 4.00 | 6.93 | 4.66 | 180 × 100 × 5.60 | 23 | 15.48 | |

| 80 × 40 × 5.00 | 8.47 | 5.7 | 180 × 100 × 6.30 | 25.4 | 17.09 | |

| 80 × 40 × 6.30 | 10.4 | 7 | 180 × 100 × 7.10 | 28.6 | 19.25 | |

| 90 × 50 × 2.60 | 5.37 | 3.61 | 180 × 100 × 8.80 | 34.7 | 23.35 | |

| 90 × 50 × 3.20 | 6.64 | 4.47 | 180 × 100 × 10.00 | 38.8 | XXVI.XI | |

| 90 × 50 × 4.00 | 8.18 | 5.51 | 180 × 100 × 12.50 | 46.9 | 31.56 | |

| 90 × 50 × 5.00 | 10 | 6.73 | 200 × 100 × 4.00 | 18 | 12.11 | |

| 90 × 50 × 6.30 | 12.3 | 8.28 | 200 × 100 × 5.00 | 22.1 | 14.2 | |

| 90 × 50 × 7.10 | 13.7 | 9.22 | 200 × 100 × 6.30 | 27.4 | 18.44 | |

| 100 × 50 × 3.60 | 7.98 | 5.37 | 200 × 100 × 8.00 | 34 | 22.88 | |

| 100 × 50 × 4.50 | 9.83 | 6.62 | 200 × 100 × 10.00 | 40.6 | 27.32 | |

| 100 × 50 × 5.60 | 12 | 8.08 | 200 × 120 × 4.00 | 19.3 | 12.99 | |

| 100 × 50 × 7.10 | 14.8 | 9.96 | 200 × 120 × 5.00 | 23.7 | 15.95 | |

| 100 × 50 × 8.00 | 16.4 | 11.04 | 200 × 120 × 6.30 | 29.6 | 19.92 | |

| 100 × 60 × 3.20 | 7.51 | 5.05 | 200 × 120 × 8.00 | 36.5 | 24.56 | |

| 100 × 60 × 3.60 | 8.55 | 5.75 | 200 × 120 × 8.80 | 36.9 | 24.83 | |

| 100 × 60 × 4.50 | 10.5 | 7.07 | 200 × 120 × 10.00 | 45.1 | 31.62 | |

| 100 × 60 × 5.60 | 12.9 | 8.68 | 200 × 120 × 12.50 | 54.7 | 38.87 | |

| 100 × 60 × 6.30 | 13.5 | 9.09 | 200 × 120 × 14.20 | 60.9 | 43.64 | |

| 100 × 60 × 7.10 | 15.9 | 10.7 | 220 × 80 × 6.00 | XXVI.DCCCXVI | 18.02 | |

| 100 × 60 × 8.80 | 19.2 | 12.92 | 220 × 120 × 6.30 | 31.6 | 21.27 | |

| 100 × 80 × 6.3 | 16.37 | 11.02 | 220 × 120 × 8.00 | 39.4 | 26.52 | |

| 110 × 60 × 3.60 | 9.05 | 6.09 | 220 × 120 × 10.00 | 46.2 | 31.09 | |

| 110 × 60 × 4.50 | 11.1 | 7.47 | 220 × 120 × 12.50 | 58.7 | 39.51 | |

| 110 × 60 × 5.60 | 13.6 | 9.15 | 220 × 120 × 14.20 | 65.4 | 44.01 | |

| 110 × 60 × 7.10 | 16.8 | 11.31 | 250 × 150 × 5.00 | 29.9 | 20.12 | |

| 110 × 60 × 8.80 | 20.1 | 13.53 | 250 × 150 × 6.30 | 37.3 | 25.1 | |

| 110 × 70 × 3.20 | 8.51 | 5.73 | 250 × 150 × 8.00 | 46.5 | 31.29 | |

| 110 × 70 × 4.00 | 10.8 | 7.27 | 250 × 150 × 10.00 | 56.3 | 37.89 | |

| 110 × 70 × 5.00 | 12.7 | 8.55 | 250 × 150 × 12.50 | 68.3 | 45.97 | |

| 110 × 70 × 6.30 | 15.5 | 10.43 | 260 × 140 × 6.30 | 37.5 | 25.23 | |

| 120 × 60 × 3.20 | 8.51 | 5.73 | 260 × 140 × 8.00 | 46.9 | 31.56 | |

| 120 × 60 × 4.00 | 10.6 | 7.13 | 260 × 140 × 10.00 | 57.6 | 38.76 | |

| 120 × 60 × 5.00 | 13 | 8.75 | 260 × 140 × 12.50 | 70.4 | 47.38 | |

| 120 × 60 × 6.30 | 16.1 | 10.84 | 260 × 140 × 14.20 | 78.8 | 53.03 | |

| 120 × 60 × 7.10 | 17.9 | 12.05 | 260 × 180 × 6.30 | 41.5 | 27.93 | |

| 120 × 60 × 8.80 | 21.5 | 14.47 | 260 × 180 × 8.00 | 52 | 35 | |

| 120 × 80 × 3.20 | 12.1 | 8.14 | 260 × 180 × 10.00 | 63.9 | 43 | |

| 120 × 80 × 6.30 | 17.5 | 11.78 | 260 × 180 × 12.50 | 78.3 | 52.7 | |

| 140 × 70 × 4.00 | 12.5 | 8.41 | 260 × 180 × 14.20 | 87.7 | 59.02 | |

| 140 × 70 × 5.00 | 15.4 | 10.36 | 300 × 100 × 5.00 | 30.268 | 20.34 | |

| 140 × 70 × 6.30 | 19 | 12.79 | 300 × 100 × 8.00 | 47.679 | 32.04 | |

| 140 × 70 × 7.10 | 21.2 | 14.27 | 300 × 100 × 10.00 | 58.979 | 39.63 | |

| 140 × 70 × 8.80 | 25.6 | 17.23 | 300 × 200 × 5.00 | 37.8 | 25.44 | |

| 140 × 80 × 3.20 | 10.5 | 7.07 | 300 × 200 × 6.30 | 47.1 | 31.7 | |

| 140 × 80 × 4.00 | 13.1 | 8.82 | 300 × 200 × 8.00 | 59.1 | 39.77 | |

| 140 × 80 × 5.00 | 16.2 | 10.9 | 300 × 200 × 10.00 | 72 | 48.46 | |

| 140 × 80 × 6.30 | 20 | 13.46 | 300 × 200 × 12.00 | 88 | 59.22 | |

| 140 × 80 × 8.00 | 24.8 | 16.69 | ||||

| 140 × 80 × 10.00 | 30.2 | 20.32 | ||||

| 150 × 100 × 3.20 | 12 | 8.08 | ||||

| 150 × 100 × 4.00 | 14.9 | 10.03 | ||||

Norma et Gradus

ASTM A500 Grade B, ASTM A513 (1020-1026), ASTM A36 (A36), EN 10210:S235, S355, S235JRH, S355J2H, S355NH, EN 10219:S235, S355, S235JRH, S275J0H, S275J2H, S355J0H, S355J2H.

| Compositio chemicatubi quadrati et rectangularesmateria | |||||

| Gradus | elementum | C | Mn | P | S |

| ASTM A500 Gr.b | % | 0.05%-0.23% | 0.3%-0.6% | 0.04% | 0.04% |

| EN10027/1 | C% max (Pondus Normale (mm)) | Si% maximum | Mn% maximum | P% maxima | S% maximum | N% maximum | |

| et IC 10 | ≤ 40 | ||||||

| S235JRH | 0.17 | 0.2 | - | 1.4 | 0.045 | 0.045 | 0.009 |

| S275JOH | 0.2 | 0.22 | - | 1.5 | 0.04 | 0.04 | 0.009 |

| S275J2H | 0.2 | 0.22 | - | 1.5 | 0.035 | 0.035 | - |

| S355JOH | 0.22 | 0.22 | 0.55 | 1.6 | 0.04 | 0.04 | 0.009 |

| S355J2H | 0.22 | 0.22 | 0.55 | 1.6 | 0.035 | 0.035 | - |

| Proprietates mechanicae materiae | |||

| Gradus | Vis Cedendi | Robur Tensilis | Elongatio |

| A500.Gr.b | 46 ksi | 58 ksi | 23% |

| A513.GR.B | 72 ksi | 87 ksi | 10% |

| Norma | Vis Cedendi | Robur Tensilis | Min.elogatio | Proprietates minimae percentuales | ||||||||

| Secundum EN10027/1 et IC 10 | Secundum EN10027/2 | Pondus Normale mm | Pondus Normale mm | Longit. | Crux | Temperatura probationis °C | Valor medius impactus minimi | |||||

| ≤16 | >6 | >40 | <3 | ≤3≤65 | Pondus Normale mm | |||||||

| ≤65 | ≤65 | ≤40 | >40 | >40 | ≤65 | |||||||

| ≤65 | ≤40 | |||||||||||

| S253JRH | 1.0039 | 235 | 225 | 215 | 360-510 | 340-470 | 26 | 25 | 24 | 23 | 20 | 27 |

| S275JOH | 1.0149 | 275 | 265 | 255 | 410-580 | 410-560 | 22 | 21 | 20 | 19 | 0 | 27 |

| S275J2H | 1.0138 | 275 | 265 | 255 | 430-560 | 410-560 | 22 | 21 | 20 | 19 | -20 | 27 |

| S355JOH | 1.0547 | 355 | 345 | 335 | 510-680 | 490-630 | 22 | 21 | 20 | 19 | 0 | 27 |

| S355J2H | 1.0576 | 355 | 345 | 335 | 510-680 | 490-630 | 22 | 21 | 20 | 19 | -20 | 27 |

| Specificationes aequivalentes | ||||

| EN 10210-1 | NF A 49501 NF A 35501 | DIN 17100 DIN 17123/4/5 | BS 4360 | UNI 7806 |

| S235JRH | E 24-2 | Sanctus 37.2 | – | Fe 360 B |

| S275JOH | E 28-3 | St 44.3 U | 43°C | Fe 430°C |

| S275J2H | E 28-4 | Via 44.3 Septentrionalis | 43 D | Fe 430 D |

| S355JOH | E 36-3 | St 52.3 U | 50°C | Fe 510°C |

| S355J2H | E 36-4 | Via 52.3 Septentrionalis | 50 D | Fe 510 D |

| S275NH | – | Via Orientalis 285 Septentrionalis | – | – |

| S275NLH | – | Via TS E 285 N | 43 EE | – |

| S355NH | E 355 R | Via Orientalis 355 Septentrionalis | – | – |

| S355NLH | – | Via TS E 355 N | 50 EE | – |

| S460NH | E 460 R | Via Orientalis 460 Septentrionalis | – | – |

| S460NLH | – | Via Orientalis 460 Septentrionalis | 55 EE | – |

Qualitatis Moderatio

Inspectio Materiae Rudis, Analysis Chemica, Examen Mechanica, Inspectio Visualis, Examen Tensionis, Examen Dimensionis, Examen Flexionis, Examen Planificationis, Examen Impactus, Examen DWT, Examen NDT, Examen Hydrostaticum, Examen Duritudinis…

Notatio, pictura ante traditionem.

Sarcina et Transportatio

Modus sarcinandi tuborum ferreorum purgationem, congregationem, involucrum, fasciculationem, firmationem, inscriptionem, palettationem (si opus est), receptacula, reponendum, obsignationem, transportationem, et disarcionem complectitur. Genera varia tuborum ferreorum et iuncturae cum variis modis sarcinandi. Hic processus comprehensivus efficit ut tubi ferrei transportentur et ad destinationem suam in optima condicione perveniant, ad usum destinatum parati.

Usus et Applicatio

Tubi ferrei quasi spina dorsalis modernae artis industrialis et civilis funguntur, amplam varietatem applicationum sustinentes quae ad progressionem societatum et oeconomiarum toto orbe conferunt.

Tubi et accessiones ferreae, quas Womic Steel producimus, late adhibitae sunt ad fistulas petrolei, gasii, cibustibilis et aquae, opera extra litus/terra, portuum maritimorum constructionis et aedificationis, dragationem, ferrum structurale, palos et pontium constructionis, necnon tubos ferreos accurati ad productionem cylindrorum transportatorum, et cetera...