Descriptio Producti

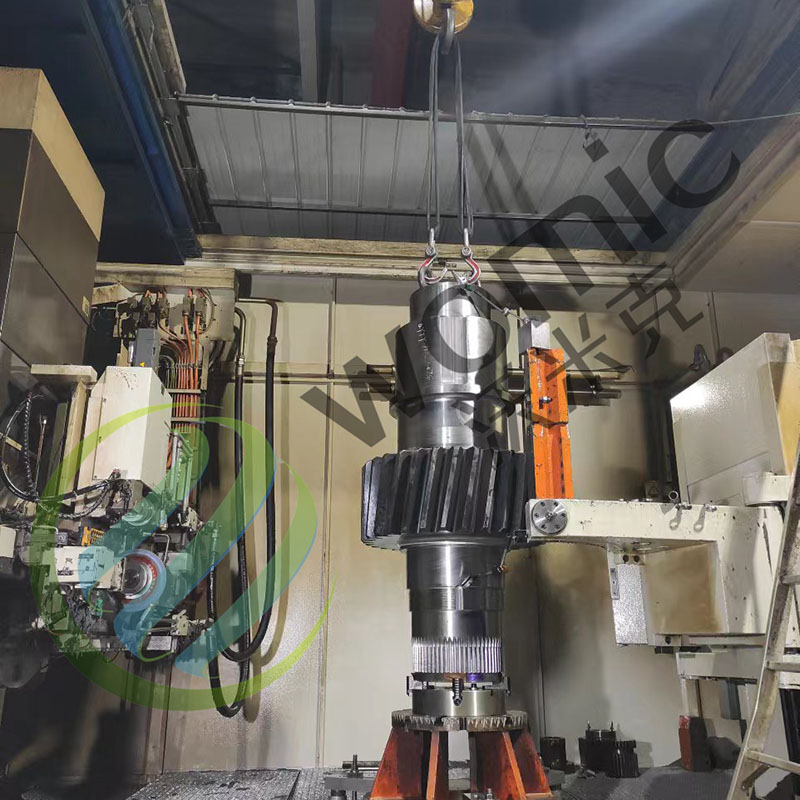

WOMIC STEEL etiam officinam fusoriam notissimam pro productis chalybis fusis et productis chalybis fabricatis in Sinis septentrionalibus habet. Multa producta chalybis fusi in totum orbem terrarum, ut in Mexico, America Meridionali, Italia, Europa, Civitatibus Foederatis Americae, Iaponiam, Russiam, Asiam Meridionalem Orientalem, et cetera, suppeditat. Cum copiosa experientia in processibus chalybis fusi et fabricati, WOMIC STEEL etiam technologiam processus continuo emendat. Rota dentata magnae molendinae globulorum, varia genera dentatarum, axis dentatus, cylindrus sustentans, ollae scoriae cupri fodinae adhibitae, machinae, partes substitutoriae palae electricae (calcei cinguli), partes contunditoris (mantelia et concava, tegumenta craterarum), et maxilla mobilis ab ea producta multos clientes transmarinos ad societatem visitandam attraxerunt, et eos de productis nostris contentos reddiderunt.

Post viginti annos experientiae productionis et venditionis in industria fusionis, nunc habemus manipulum technicum peritum et doctum, in productione fusionum chalybis magnarum et extra magnarum specializatum. Processus productionis utitur fusione communi, ordinatione semel tantum chalybis fusi 450 talentorum, et maximum pondus singulare fusionum circiter 300 talentorum attingere potest. Industria productorum comprehendit fodinas, cementum, naves, fabricationem machinationis, metallurgiam, pontes, conservationem aquarum, unum centrum machinationis (coetus) (quinque machinae terebrantes et fresantes CNC TK6920, tredecim tornus verticales duplicis columnae CNC 3.15M~8M (coetus), una machina CNC 120x3000 ad laminas volvendas, sex series machinarum φ1.25m-8m ad dentes perforandos (coetus)), et cetera.

Instrumenta productionis et instrumenta probationis completa sunt. Maxima capacitas elevationis unius vehiculi est trecentae talentorum, cum uno camino arcus electrici triginta et octoginta talentorum, uno camino refinatorio LF duplici statione centum viginti talentorum, una machina iaculatoria cum mensa rotatoria decem metrorum et decem metrorum, tribus furnis curationis caloris altae temperaturae duodecim metrorum et septem metrorum et quinque metrorum, octo metrorum et quattuor metrorum et tres et octo metrorum et quattuor metrorum et tres tres. Area filtrationis triginta milia metrorum quadratorum est, instrumenta ad pulverem removendum in camino arcus electrici includentia.

Centrum probationum independens laboratorio chemico, spectrometro lectionis directae, machina ad impactum probandum, machina ad tensionem probandam, detectore vitiorum ultrasonico, duritiae probatore Leeb, microscopio phasis metallographico, et cetera, instructum est.

Inspectiones in situ quovis tempore a nobis accipiuntur, ut tibi persuadeas fusuras ferreas et producta fabricata a WOMIC STEEL producta bonam qualitatem et longam vitam utilem habere, quae et requisitis designandi clientium bene satisfacere possint.

Ad condicionem magnae pollutionis et magnae energiae consumptionis solvendam,

WOMIC STEEL furnos electricos frequentiae mediae adhibet et collectores pulveris in officina instituit. Nunc, ambitus laboris officinae insigniter emendatus est. Olim, coca combusta est, sed nunc electricitas adhibetur, quae non solum consumptionem energiae minuit, energiam conservat et ambitum protegit, sed etiam accuratiam producti auget.

WOMIC STEEL ferramenta officinae porro emendabit, apparatum automationis adiuvans, applicationem rationum automaticarum ad partes colligendas, purgandas et poliendas, et aspersionem automaticam, et cetera, ut gradus automationis processus productionis ad plus quam 90% augeatur, et technologiam emendare pergat.

Differentia inter producta chalybis fusa et producta chalybis fabricata:

Primo, processus productionis differt

Processus productionis elementorum fusorum et chalybis fusorum differt. Chalybs fusus ad omnia genera materiarum fusarum et elementorum fusorum per methodum fusoriam productorum refertur; chalybs fusus est chalybs ad fusa fundenda adhibitus. Fusio est laminatio materiarum crudarum in formam et magnitudinem desideratam per impactum et deformationem plasticam materiarum metallicarum. Contra, fusa chalybis fiunt infuso metallo fuso in exemplar praeparatum, quod solidificatur et refrigeratur ut forma et magnitudo desiderata obtineatur. Chalybs fusus saepe in fabricatione quarundam partium machinarum magni momenti adhibetur; chalybs fusus praecipue ad fabricandas quasdam formas complexas adhibetur, quae difficiles sunt ad fusum vel secendum et partes magnae firmitatis et plasticitatis requirunt.

Secundo, structura materiae differt.

Structura materiae etiam e ferro fuso et e ferro fuso differt. Fusi plerumque aequabiliores sunt et meliorem firmitatem atque resistentiam lassitudinis habent. Propter structuram crystallinam relative densam, non deformationi nec fissuris thermalibus obnoxiae sunt cum onere subiciuntur. Contra, structura ferri fusi relative laxa est, quae facile deformationem plasticam et damnum lassitudinis sub actione oneris producit.

Tertio, proprietates perfunctionis diversae

Proprietates functionis partium fusarum et fabricatarum etiam differunt. Fabricata magnam resistentiam attritionis et corrosionis habent et apta sunt oneribus magnae firmitatis et frequentiae. Contra, resistentia attritionis et corrosionis partium chalybis fusae relative malae sunt, sed bonam plasticitatem habent.