Descriptio Producti

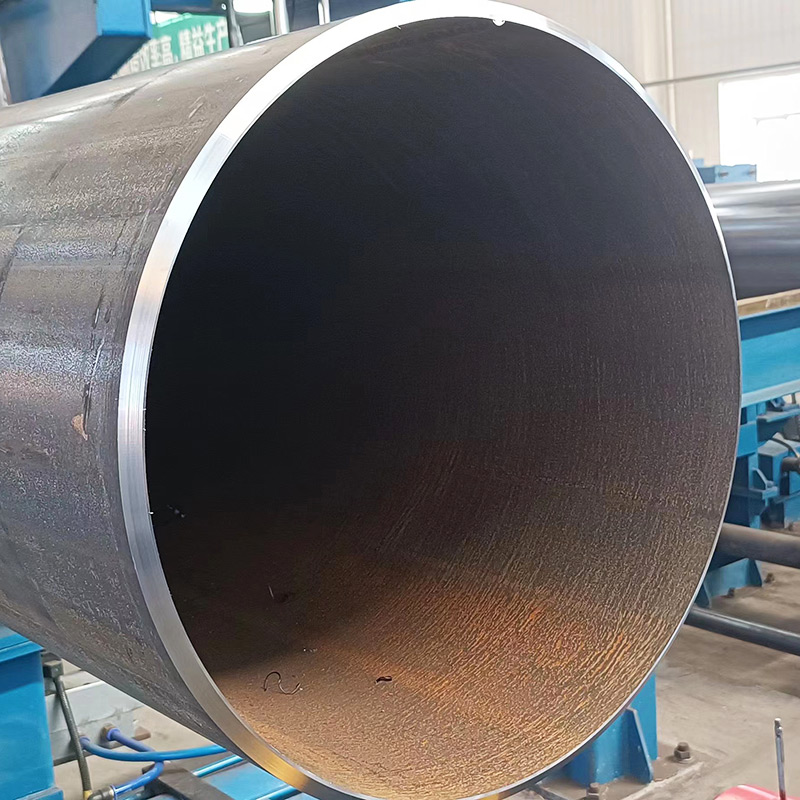

Tubi ferrei LSAW (Longitudinal Submerged Arc Welding) sunt genus tubi ferrei conglutinati, quod singulari processu fabricationis et lata applicationum varietate insignitur. Hi tubi fabricantur lamina ferrea in formam cylindricam formando et eam longitudinaliter conglutinando utens technicis conglutinationis arcus submersi. Hic est conspectus tuborum ferreorum LSAW:

Processus Fabricationis:

● Praeparatio Laminarum: Laminae chalybis altae qualitatis secundum requisita specifica eliguntur, proprietates mechanicas et compositionem chemicam desideratas curantes.

● Formatio: Lamina ferrea in tubum cylindricum per processus ut flexionem, volutationem, vel pressionem (JCOE et UOE) formatur. Margines praecurvantur ad soldaduram faciliorem reddendam.

● Soldatura: Soldatura arcus submersi (SAW) adhibetur, ubi arcus sub strato fluxus servatur. Hoc producit suturas altae qualitatis cum minimis vitiis et optima fusione.

● Inspectio Ultrasonica: Post soldaduram, probatio ultrasonica perficitur ad vitia interna vel externa in zona soldadurae detegenda.

● Expansio: Tubus expandi potest ad diametrum et crassitudinem parietis desideratam assequendam, quo accuratio dimensionalis augetur.

● Inspectio Finalis: Examinatio completa, inter quas inspectio visualis, probationes dimensionales, et probationes proprietatum mechanicarum, qualitatem tubi confirmat.

Commoda:

● Efficientia Impensarum: Tubi LSAW solutionem efficientem sumptibus praebent pro canalibus magni diametri et applicationibus structuralibus propter efficientem processum fabricationis.

● Alta Robur: Methodus soldadurae longitudinalis tubos cum proprietatibus mechanicis firmis et uniformibus efficit.

● Accuratio Dimensionalis: Tubi LSAW dimensiones accuratas exhibent, ita ut ad usus cum tolerantiis strictis apti sint.

● Qualitas Suturae: Sutura arcus submersi producit suturas altae qualitatis cum fusione excellenti et vitiis minimis.

● Versatilitas: Tubi LSAW in variis industriis, inter quas oleum et gas, aedificatio, et aquae subministratio, propter adaptabilitatem et durabilitatem adhibentur.

Summa summarum, tubi ferrei LSAW processu accurato et efficaci fabricantur, quod efficit ut tubi versatiles, sumptibus parcissimi, et durabiles sint, apti ad amplam varietatem applicationum industrialium.

Specificationes

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| ASTM A252: GR.1, GR.2, GR.3 |

| EN 10219-1: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A53/A53M: GR.A, GR.B |

| EN 10217: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| DIN 2458: St37.0, St44.0, St52.0 |

| AS/NZS 1163: Gradus C250, Gradus C350, Gradus C450 |

| GB/T 9711: L175, L210, L245, L290, L320, L360, L390, L415, L450, L485. |

| ASTMA671: CA55/CB70/CC65, CB60/CB65/CB70/CC60/CC70, CD70/CE55/CE65/CF65/CF70, CF66/CF71/CF72/CF73, CG100/CH100/CI100/CJ100 |

Series Productionis

| Diameter Externus | Crassitudo parietis praesto pro gradu ferri infra | |||||||

| Uncia | mm | Gradus Chalybis | ||||||

| Uncia | mm | L245 (Gr.B) | L290(X42) | L360(X52) | L415(X60) | L450(X65) | L485(X70) | L555(X80) |

| 16 | 406 | 6.0-50.0mm | 6.0-48.0mm | 6.0-48.0mm | 6.0-45.0mm | 6.0-40mm | 6.0-31.8mm | 6.0-29.5mm |

| 18 | 457 | 6.0-50.0mm | 6.0-48.0mm | 6.0-48.0mm | 6.0-45.0mm | 6.0-40mm | 6.0-31.8mm | 6.0-29.5mm |

| 20 | 508 | 6.0-50.0mm | 6.0-50.0mm | 6.0-50.0mm | 6.0-45.0mm | 6.0-40mm | 6.0-31.8mm | 6.0-29.5mm |

| 22 | 559 | 6.0-50.0mm | 6.0-50.0mm | 6.0-50.0mm | 6.0-45.0mm | 6.0-43mm | 6.0-31.8mm | 6.0-29.5mm |

| 24 | DCX | 6.0-57.0mm | 6.0-55.0mm | 6.0-55.0mm | 6.0-45.0mm | 6.0-43mm | 6.0-31.8mm | 6.0-29.5mm |

| 26 | DCCLX | 6.0-57.0mm | 6.0-55.0mm | 6.0-55.0mm | 6.0-48.0mm | 6.0-43mm | 6.0-31.8mm | 6.0-29.5mm |

| 28 | DCCXI | 6.0-57.0mm | 6.0-55.0mm | 6.0-55.0mm | 6.0-48.0mm | 6.0-43mm | 6.0-31.8mm | 6.0-29.5mm |

| 30 | DCCCLXII | 7.0-60.0mm | 7.0-58.0mm | 7.0-58.0mm | 7.0-48.0mm | 7.0-47.0mm | 7.0-35mm | 7.0-32.0mm |

| 32 | DCCCXIII | 7.0-60.0mm | 7.0-58.0mm | 7.0-58.0mm | 7.0-48.0mm | 7.0-47.0mm | 7.0-35mm | 7.0-32.0mm |

| 34 | DCCCLXIV | 7.0-60.0mm | 7.0-58.0mm | 7.0-58.0mm | 7.0-48.0mm | 7.0-47.0mm | 7.0-35mm | 7.0-32.0mm |

| 36 | 914 | 8.0-60.0mm | 8.0-60.0mm | 8.0-60.0mm | 8.0-52.0mm | 8.0-47.0mm | 8.0-35mm | 8.0-32.0mm |

| 38 | 965 | 8.0-60.0mm | 8.0-60.0mm | 8.0-60.0mm | 8.0-52.0mm | 8.0-47.0mm | 8.0-35mm | 8.0-32.0mm |

| 40 | 1016 | 8.0-60.0mm | 8.0-60.0mm | 8.0-60.0mm | 8.0-52.0mm | 8.0-47.0mm | 8.0-35mm | 8.0-32.0mm |

| 42 | 1067 | 8.0-60.0mm | 8.0-60.0mm | 8.0-60.0mm | 8.0-52.0mm | 8.0-47.0mm | 8.0-35mm | 8.0-32.0mm |

| 44 | 1118 | 9.0-60.0mm | 9.0-60.0mm | 9.0-60.0mm | 9.0-52.0mm | 9.0-47.0mm | 9.0-35mm | 9.0-32.0mm |

| 46 | 1168 | 9.0-60.0mm | 9.0-60.0mm | 9.0-60.0mm | 9.0-52.0mm | 9.0-47.0mm | 9.0-35mm | 9.0-32.0mm |

| 48 | 1219 | 9.0-60.0mm | 9.0-60.0mm | 9.0-60.0mm | 9.0-52.0mm | 9.0-47.0mm | 9.0-35mm | 9.0-32.0mm |

| 52 | 1321 | 9.0-60.0mm | 9.0-60.0mm | 9.0-60.0mm | 9.0-52.0mm | 9.0-47.0mm | 9.0-35mm | 9.0-32.0mm |

| 56 | 1422 | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

| 60 | MDXXIV | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

| 64 | 1626 | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

| 68 | MDCCXXVII | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

| 72 | MDCCCXXIX | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

* Aliae magnitudines post negotiationem aptari possunt

Compositio Chemica et Proprietates Mechanicae Tubi Chalybis LSAW

| Norma | Gradus | Compositio Chemica (max)% | Proprietates Mechanicae (min) | |||||

| C | Mn | Si | S | P | Robur Cessationis (Mpa) | Robur tensile (Mpa) | ||

| GB/T700-2006 | A | 0.22 | 1.4 | 0.35 | 0.050 | 0.045 | 235 | 370 |

| B | 0.2 | 1.4 | 0.35 | 0.045 | 0.045 | 235 | 370 | |

| C | 0.17 | 1.4 | 0.35 | 0.040 | 0.040 | 235 | 370 | |

| D | 0.17 | 1.4 | 0.35 | 0.035 | 0.035 | 235 | 370 | |

| GB/T1591-2009 | A | 0.2 | 1.7 | 0.5 | 0.035 | 0.035 | 345 | 470 |

| B | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

| C | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

| BS EN10025 | S235JR | 0.17 | 1.4 | - | 0.035 | 0.035 | 235 | 360 |

| S275JR | 0.21 | 1.5 | - | 0.035 | 0.035 | 275 | 410 | |

| S355JR | 0.24 | 1.6 | - | 0.035 | 0.035 | 355 | 470 | |

| DIN 17100 | ST37-2 | 0.2 | - | - | 0.050 | 0.050 | 225 | 340 |

| ST44-2 | 0.21 | - | - | 0.050 | 0.050 | 265 | 410 | |

| ST52-3 | 0.2 | 1.6 | 0.55 | 0.040 | 0.040 | 345 | 490 | |

| JIS G3101 | SS400 | - | - | - | 0.050 | 0.050 | 235 | quadringenti |

| SS490 | - | - | - | 0.050 | 0.050 | 275 | 490 | |

| API 5L PSL1 | A | 0.22 | 0.9 | - | 0.03 | 0.03 | 210 | 335 |

| B | 0.26 | 1.2 | - | 0.03 | 0.03 | 245 | 415 | |

| X42 | 0.26 | 1.3 | - | 0.03 | 0.03 | 290 | 415 | |

| X46 | 0.26 | 1.4 | - | 0.03 | 0.03 | 320 | 435 | |

| X52 | 0.26 | 1.4 | - | 0.03 | 0.03 | 360 | 460 | |

| X56 | 0.26 | 1.1 | - | 0.03 | 0.03 | 390 | 490 | |

| X60 | 0.26 | 1.4 | - | 0.03 | 0.03 | 415 | 520 | |

| X65 | 0.26 | 1.45 | - | 0.03 | 0.03 | 450 | 535 | |

| X70 | 0.26 | 1.65 | - | 0.03 | 0.03 | 585 | 570 | |

Norma et Gradus

| Norma | Gradus Ferri |

| API 5L: Specificatio pro Tubo Lineari | GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| ASTM A252: Specificatio Standardis pro Palis Tuborum Chalybeorum Conglutinatis et Sinsuratis | Gradus Primus, Gradus Secundus, Gradus Tertius |

| EN 10219-1: Sectiones Cavae Structurales Frigidae et Soldatae ex Chalybe Non-Mixto et Grano Tenui | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: Sectiones Cavae Structurales Calido Perfectae ex Chalybe Non-Mixto et Grano Tenui | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A53/A53M: Tubus, Chalybeus, Niger et Calido Intinctus, Zinco Obductus, Soldatus et Sine Suturitate | GRADUS A, GRADUS B |

| EN10208: Tubi ferrei ad usum in systematibus translationis per fistulas in industriis petrolei et gasi naturalis. | L210GA, L235GA, L245GA, L290GA, L360GA |

| EN 10217: Tubi Ferrei Conglutinati ad Usus Pressionis | P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| DIN 2458: Tubi et Tubi Ferrei Conglutinati | St37.0, St44.0, St52.0 |

| AS/NZS 1163: Norma Australiana/Novae Zelandiae pro Sectionibus Cavis Chalybis Structuralis Frigide Formatis | Gradus C250, Gradus C350, Gradus C450 |

| GB/T 9711: Industriae Petrolei et Gasis Naturalis - Tubus Ferreus pro Tubis | L175, L210, L245, L290, L320, L360, L390, L415, L450, L485 |

| ASTM A671: Tubus Chalybeus Electrico-Fusus-Conglutinatus ad Temperamenta Atmosphaerica et Inferiora | CA 55, CB 60, CB 65, CB 70, CC 60, CC 65, CC 70 |

| ASTM A672: Tubus ferreus per fusionem electricam conglutinatus ad usum altae pressionis sub temperaturis moderatis. | A45, A50, A55, B60, B65, B70, C55, C60, C65 |

| ASTM A691: Tubus ex chalybe carbonico et mixto, per fusionem electricam conglutinatus, ad usum altae pressionis sub temperaturis altis. | CM-65, CM-70, CM-75, 1/2CR-1/2MO, 1CR-1/2MO, 2-1/4CR, 3CR |

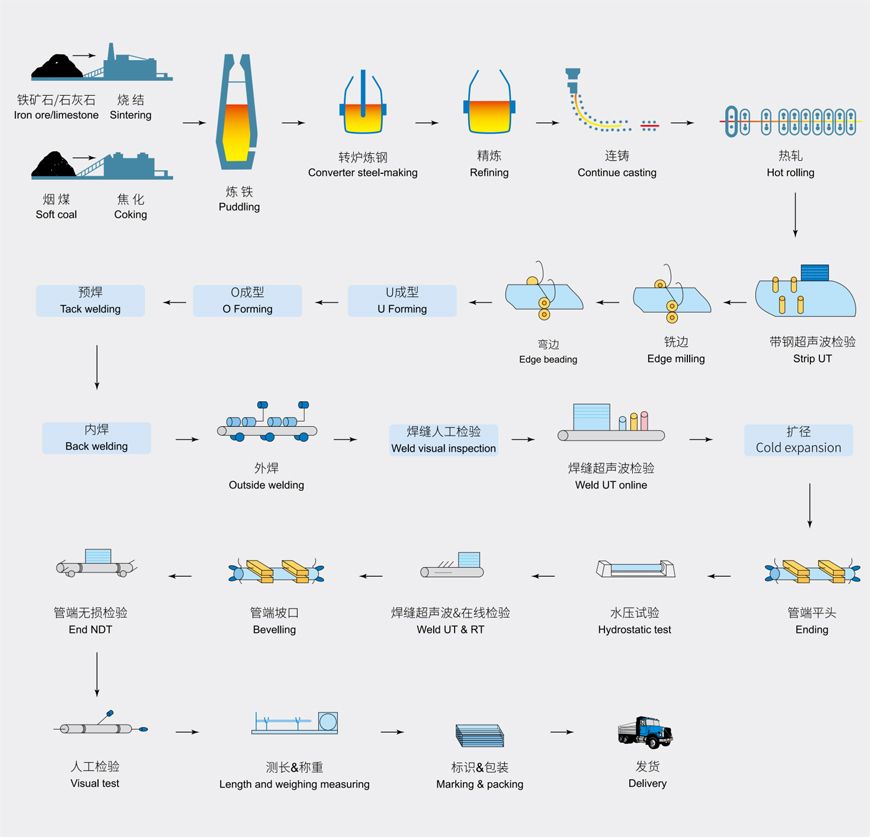

Processus Fabricationis

Qualitatis Moderatio

● Inspectio Materiae Crudae

● Analysis Chemica

● Examen Mechanicale

● Inspectio Visualis

● Dimensionum Inspectio

● Examen Flexionis

● Examen Impactus

● Examen Corrosionis Intergranularis

● Examen Non Destructivum (UT, MT, PT)

● Qualificatio Procedurae Soldandi

● Analysis Microstructurae

● Examen Expansionis et Applanationis

● Examen Duritiae

● Examen Hydrostaticum

● Examen Metallographiae

● Examen Fissurae Hydrogenio Inductae (HIC)

● Examen Fracturae Stress Sulfidi (SSC)

● Examen Currentis Turbinis

● Inspectio Picturae et Tegumentorum

● Recensio Documentorum

Usus et Applicatio

Tubi ferrei LSAW (Longitudinal Submerged Arc Welding) propter integritatem structuralem et versatilitatem varias applicationes in variis industriis inveniunt. Infra sunt nonnulli usus et applicationes praecipui tuborum ferreorum LSAW:

● Transportatio Olei et Gasis: Tubi ferrei LSAW late in industria olei et gasis pro systematibus fistularum adhibentur. Hi tubi ad transportationem olei crudi, gasis naturalis, et aliorum fluidorum vel gasorum adhibentur.

● Infrastructura Aquatica: Tubi LSAW in inceptis infrastructurae aquaticae adhibentur, inter quas systemata aquae suppeditandae et exhauriendae.

● Processus Chemicus: Tubi LSAW in industriis chemicis serviunt ubi ad chemica, liquida et gasa modo tuto et efficaci transportanda adhibentur.

● Aedificatio et Infrastructura: Hae fistulae in variis operibus aedificatoriis, ut in fundamentis aedificiorum, pontibus, aliisque applicationibus structuralibus, adhibentur.

● Pali figendi: Tubi LSAW in palis figendi adhibentur ad fundamenta sustentanda in operibus constructionis, inter quae fundamenta aedificiorum et structurae maritimae.

● Sector Energiae: Ad varias energiae formas transportandas adhibentur, inter quas vapor et fluida thermica in stationibus generationis energiae.

● Fodinae: Tubi LSAW usum in proiectis fodinarum ad materias et reliquias transportandas inveniunt.

● Processus Industriales: Industriae sicut fabricatio et productio tubos LSAW ad varios processus industriales utuntur, inter quos sunt transportatio materiarum crudarum et productorum perfectorum.

● Progressus Infrastructurarum: Hae fistulae necessariae sunt in progrediendis inceptis infrastructurarum, ut viis, autoviis, et utilitatibus subterraneis.

● Sustentamenta Structuralia: Tubi LSAW ad fabricanda sustentamenta structuralia, columnas et trabes in constructione et inceptis machinalibus adhibentur.

● Navium aedificatio: In industria navium aedificandarum, tubi LSAW ad varias partes navium construendas, inter quas sunt corpus et elementa structuralia, adhibentur.

● Industria Autocinetica: Tubi LSAW in fabricatione partium autocineticarum, inter quas systemata exhaustoria, adhiberi possunt.

Hae applicationes versatilitatem tuborum ferreorum LSAW per varios sectores demonstrant, propter firmitatem, robur, et aptitudinem ad varias condiciones ambientales.

Sarcina et Transportatio

Recta sarcinatio et vectura tuborum ferreorum LSAW (Longitudinal Submerged Arc Welding) necessaria est ad eorum transportationem et traditionem tutam ad varia loca. Hic est descriptio rationum typicarum sarcinationis et vecturae tuborum ferreorum LSAW:

Sarcina:

● Fasciculatio: Tubi LSAW saepe fasciculatim congeruntur vel singulatim fasciculantur utens loris ferreis vel taeniis ut unitates tractabiles ad transportandum et transportandum creentur.

● Protectio: Extremitates tuborum operculis plasticis proteguntur ne damnum in itinere inferatur. Praeterea, tubi materia tutelari tegi possunt ut contra factores externos protegantur.

● Tegumentum Anti-Corrosionis: Si tubi tegumento anticorrosionis utuntur, integritas tegumenti per sarcinandum curatur ne damnum fiat in tractatione et transportatione.

● Notatio et Inscriptiones: Quisque fasciculus informationibus essentialibus, ut magnitudine tubi, genere materiae, numero caloris, aliisque specificationibus ad facilem identificationem, inscriptus est.

● Firmatio: Fasciculi firmiter ad palletas vel patinas adligantur ne motus durante transportatione oriantur.

Navigatio:

● Modi Transportationis: Tubi ferrei LSAW variis modis transportationis, inter quos via, ferrivia, mari, vel aere, pro destinatione et necessitate transportari possunt.

● Containerizatione: Tubi in containeribus transportari possunt ad maiorem tutelam, praesertim durante vectura transmarina. Containeres onerantur et muniuntur ne moveantur durante itinere.

● Socii Logisticorum: Societates logisticae bonae famae vel vectores in tractandis tubis ferreis periti conducuntur ut traditionem tutam et tempestivam curent.

● Documenta Vectigalia: Documenta vectigalia necessaria, inter quae litteris onerariis, testimonia originis, et alia documenta pertinentia, parantur et pro vecturis internationalibus submittuntur.

● Assicuratio: Pro valore et natura mercium, assecuratio ordinari potest ad tutelam contra casus improvisos in itinere.

● Investigatio: Systemata investigationis moderna permittunt et mittenti et accipienti progressum vecturae in tempore reali sequi, perspicuitatem et renovationes opportunas curantes.

● Traditio: Tubi ad locum destinatum exonerantur, debitis proceduris exonerationis secutis ne damnum inferantur.

● Inspectio: Post adventum, tubi inspectionem subire possunt ut condicio earum et congruentia cum specificationibus comprobentur antequam a destinatario accipiantur.

Rectae rationes sarcinandi et transportandi adiuvant ad damnum prohibendum, integritatem tuborum ferreorum LSAW conservandam, et curandum ut ad destinatum locum tuto et in optima condicione perveniant.