Introductio:

API 5L est specificatio norma ab Instituto Petrolei Americano (API) constituta pro tubis ferreis sine suturis et conglutinatis, quae in systematibus translationis intra industrias petrolei et gasi naturalis adhibentur. Womic Steel, fabricator princeps tuborum API 5L, seriem productorum amplam offert quae variis gradibus et specificationibus satisfaciunt. Hic articulus comparationem accuratam compositionis chemicae, proprietatum mechanicarum, et normarum probationum pro diversis gradibus API 5L, tam PSL1 quam PSL2, per tria genera tuborum praebet: ERW (Conglutinatae per Resistentiam Electricam), LSAW (Conglutinatae per Arcum Submersum Longitudinaliter), et SMLS (Sine Suturis).

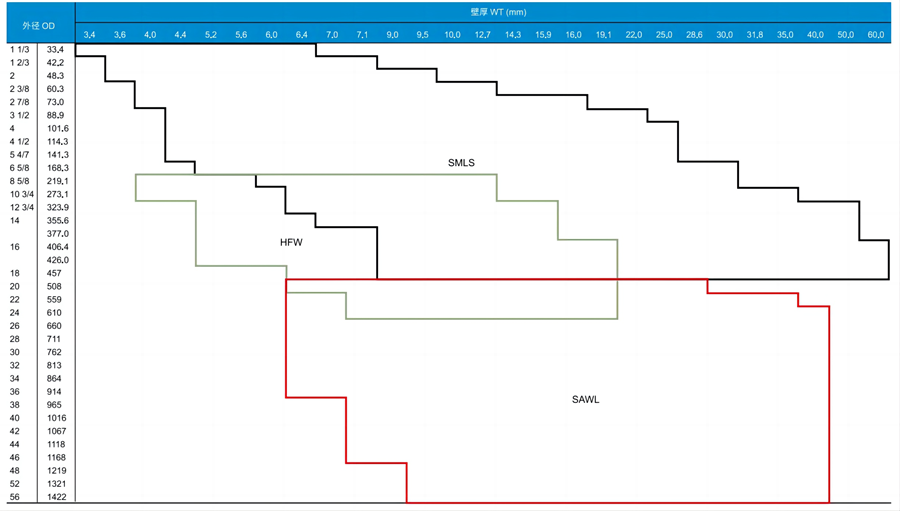

Capacitas Productionis et Ambitus:

| 制造方法 | 钢级起 | 钢级止 | 外径起 OD Min. mm | 外径止 | 壁厚起 | 壁厚止 | 生产能力 |

| SMLS | B | X80Q | 33.4 | 457 | 3.4 | 60 | Viginti milia |

| HFW | B | X80M | 219.1 | DCX | 4.0 | 19.1 | Viginti milia |

| SAWL | B | X100M | 508 | 1422 | 6.0 | 40 | Quinque milia |

Tolerantia Diametri Externi

| 标准 | 外径范围 | 外径公差 | 椭圆度 | ||||

| 管体 | 管端 | 管体 | 管端 | ||||

| 无缝 | 焊管 | 无缝 | 焊管 | 无缝 | 焊管 | ||

| API SPEC SO 3183 | Diametros <60.3mm | +0.4mm/-0.8mm | +1.6mm/-0.4mm | ||||

| 60.3mm ≤ D ≤ 168.3mm | +0.75%/-0.75% | ≤2.0% | ≤1.5% | ||||

| 168.3mm | +0.5%/-0.5% | ||||||

| 320mm | +1.6mm/-1.6mm | ||||||

| 426mm | +0.75%/-0.75% | +3.2mm/-3.2mm | |||||

| 610mm | +1.0%/-1.0% | +0.5%/-0.5% | ±2.0mm | ±1.6mm | ≤1.5% | ≤1.0% | |

| 800mm | +4mm/-4mm | ||||||

| 1000mm | +1.0%/-1.0% | +4mm/-4mm | ≤15mm | ≤1.0% | |||

| 1300mm | +1.0%/-1.0% | +4mm/-4mm | ≤15mm | ≤13mm | |||

Nota: D est diameter exterior nominalis tubi.

Tolerantia Crassitudinis Muri

| 标准 | 外径范围 | 壁厚范围 | 壁厚公差 | 壁厚公差 |

| 无缝 | 焊管 | |||

| API SPEC ISO 3183 | - | t≤4.0mm | +0.6mm/-0.5mm | +0.5mm/-0.5mm |

| - | 4.0mm | +15%/-12.5% | ||

| - | 5.0mm | +10%/-10% | ||

| - | 15.0mmst <25.0mm | +1.5mm/-1.5mm | ||

| - | 25.0mm ≤ t < 30.0mm | +3.7mm/-3.0mm | ||

| - | 30.0mm ≤ t < 37.0mm | +3.7mm/-10.0% | ||

| - | t≥37.0mm | +10.0%/-10.0% |

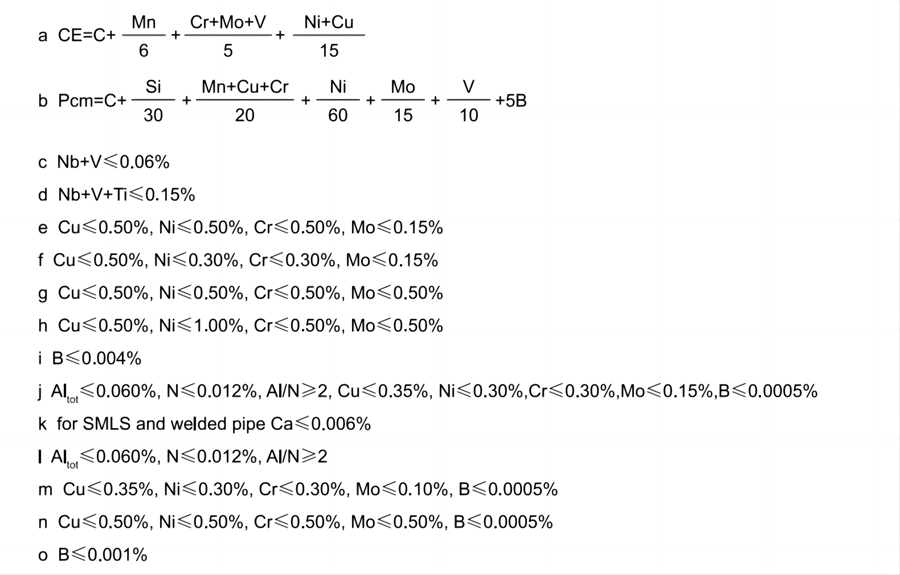

Analysis Chemica

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | T | CE | PCM | 备注 |

| maximum | maximum | maximum | maximum | maximum | maximum | maximum | maximum | maximum | maximum | |||||

| API SPEC 5L | 无缝管 | PSL1 | L210 vel A | 0.22 |

| 0.90 | 0.030 | 0.030 |

|

|

|

|

| e,o |

| L245 vel B | 0.28 |

| 1.20 | 0.030 | 0.030 |

|

|

|

|

| c, d, e, o | |||

| L290 vel X42 | 0.28 |

| 1.30 | 0.030 | 0.030 |

|

|

|

|

| de,o | |||

| L320 vel X46 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L360 vel X52 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L390 vel X56 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L415 vel X60 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L450 vel X65 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| de,o | |||

| L485 vel X70 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| PSL2 | L245N vel BN | 0.24 | 0.40 | 1.20 | 0.025 | 0.015 |

|

| 0.04 | 0.43 | 0.25 | c, f, o | ||

| L290N vel X42N | 0.24 | 0.40 | 1.20 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320N vel X46N | 0.24 | 0.40 | 1.40 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | 0.43 | 0.25 | d, f, o | |||

| L360N vel X52N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d, f, o | |||

| L390N vel X56N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d, f, o | |||

| L415N vel X60N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | Ut convenerat | d, g, o | ||||

| L245Q vel BQ | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L290Q vel X42Q | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320Q vel X46Q | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| 13600 vel ×52Q | 0.18 | 0.45 | 1.50 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L390Q vel X56Q | 0.18 | 0.45 | 1.50 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | 0.43 | 0.25 | d, f, o | |||

| L415Q vel X60Q | 0.18 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d, g, o | |||

| L450Q vel X65Q | 0.18 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d, g, o | |||

| L485Q vel X70Q | 0.18 | 0.45 | 1.80 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d, g, o | |||

| L555Q vel X80Q | 0.18 | 0.45 | 1.90 | 0.025 | 0.015 |

|

|

| Ut convenerat | h,i | ||||

| 酸性服 | L245NS vel BNS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 |

|

| 0.04 | 0.36 | 0.22 | c, d, j, k | ||

| L290NS vel X42NS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.05 | 0.05 | 0.04 | 0.36 | 0.22 | j,k | |||

| L320NS vel X46NS | 0.14 | 0.40 | 1.40 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.38 | 0.23 | dj,k | |||

| L360NS vel X52NS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d, j, k | |||

| L245QS vel BQS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | j,k | |||

| L290QS vel X42QS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | j,k | |||

| L320QS vel X46QS | 0.15 | 0.45 | 1.40 | 0.020 | 0.008 | 0.05 | 0.05 | 0.04 | 0.36 | 0.23 | j,k | |||

| L360QS vel X52QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.39 | 0.23 | d, j, k | |||

| L390QS vel X56QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.40 | 0.24 | d, j, k | |||

| L415QS vel X60QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.08 | 0.05 | 0.04 | 0.41 | 0.25 | dj,k | |||

| L450QS vel X65QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d, j, k | |||

| L485QS vel X70QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,j,k | |||

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | Ti | CEa | PCM | 备注 |

| maximum | maximum | maximum | maximum | maximum | maximum | maximum | maximum | maximum | maximum | |||||

| AP|SPEC 5L | 无缝管 | 海上服 | L245NO vel BNO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 |

|

| 0.04 | 0.36 | 0.22 | c, d, I, m |

| L290NO vel X42NO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 | 0.36 | 0.22 | l,m | |||

| L320NO vel X46NO | 0.14 | 0.40 | 1.40 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.38 | 0.23 | d,I,m | |||

| L360NO vel X52NO | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,I | |||

| L245QO vel BQO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | l,m | |||

| L290QO vel X42Q0 | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | l,m | |||

| L320QO vel X46QO | 0.15 | 0.45 | 1.40 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 | 0.36 | 0.23 | l,m | |||

| L360QO vel X52QO | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.39 | 0.23 | d,I,n | |||

| L390QO vel X56Q0 | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.40 | 0.24 | d,I,n | |||

| L415QO vel X60QO | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.08 | 0.05 | 0.04 | 0.41 | 0.25 | d,I,n | |||

| L455QO vel X65QO | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,I,n | |||

| L485Q0 vel X70Q0 | 0.17 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.05 | 0.06 | 0.42 | 0.25 | d, l, n | |||

| L555QO vel X80QO | 0.17 | 0.45 | 1.85 | 0.020 | 0.010 | 0.10 | 0.06 | 0.06 | Ut convenerat | d,I,n | ||||

| 焊管 | PSL1 | L245 vel B | 0.26 |

| 1.20 | 0.030 | 0.030 |

|

|

|

|

| cd,e,c | |

| L290 vel X42 | 0.26 |

| 1.30 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L320 vel X46 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L360 vel X52 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L390 vel X56 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L415 vel X60 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L450 vel X65 | 0.26 |

| 1.45 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L485 vel X70 | 0.26 |

| 1.65 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| PSL2 | 1245M vel BM | 0.22 | 0.45 | 1.20 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | ||

| L290M vel X42M | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320M vel X46M | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L360M vel X52M | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d, f, o | |||

| L390M vel X56M | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d, f, o | |||

| L415M vel X60M | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d, g, o | |||

| L450M vel X65M | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d, g, o | |||

| L485M vel X70M | 0.12 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d, g, o | |||

| L555M vel X80M | 0.12 | 0.45 | 1.85 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d, g, o | |||

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | T | CEa | PCM | 备注 |

| maximum | maximum | maximum | maximum | maximum | maximum | maximum | maximum | maximum | maximum | |||||

| API SPEC 5L | 焊管 | 酸性服 | L245MS vel BMS | 0.10 | 0.40 | 1.25 | 0.020 | 0.002 | 0.04 | 0.04 | 0.04 |

| 0.19 | j,k |

| L290MS vel X42MS | 0.10 | 0.40 | 1.25 | 0.020 | 0.002 | 0.04 | 0.04 | 0.04 |

| 0.19 | j,k | |||

| L320MS vel X46MS | 0.10 | 0.45 | 1.35 | 0.020 | 0.002 | 0.05 | 0.05 | 0.04 |

| 0.20 | j,k | |||

| L360MS vel X52MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.05 | 0.06 | 0.04 |

| 0.20 | j,k | |||

| L390MS vel X56MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.06 | 0.08 | 0.04 |

| 0.21 | d, j, k | |||

| L415MS vel X60MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.08 | 0.08 | 0.06 |

| 0.21 | d, j, k | |||

| L450MS vel X65MS | 0.10 | 0.45 | 1.60 | 0.020 | 0.002 | 0.10 | 0.08 | 0.06 |

| 0.22 | d, j, k | |||

| L485MS vel X70MS | 0.10 | 0.45 | 1.60 | 0.020 | 0.002 | 0.10 | 0.08 | 0.06 |

| 0.22 | dj,k | |||

| 海上服 | L245MO vel BMO | 0.12 | 0.40 | 1.25 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 |

| 0.19 | l,m | ||

| L290MO vel X42MO | 0.12 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 |

| 0.19 | l,m | |||

| L320MO vel X46MO | 0.12 | 0.45 | 1.35 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 |

| 0.20 | Ego sum | |||

| L360MO vel X52MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 |

| 0.20 | d,I,n | |||

| L390MO vel X56MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.06 | 0.08 | 0.04 |

| 0.21 | d, l, n | |||

| L415MO vel X60MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.08 | 0.08 | 0.06 |

| 0.21 | d,I,n | |||

| L450MO vel X65MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.222 | d,I,n | |||

| L485MO vel X70MO | 0.12 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.22 | d, l, n | |||

| L555MO vel X80MO | 0.12 | 0.45 | 1.85 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.24 | d,I,n |

| 标准 | 等级 | 钢级 |

| 屈服强度 | 抗拉强度 | 延伸率 | 屈强比 | 焊缝抗拉强度 |

| API SPEC 5L | PSL1 | L210 vel A | Min. | 210 | 335 | a |

| 335 |

| L245 vel B | Min. | 245 | 415 | a |

| 415 | ||

| L290 vel X42 | Min. | 290 | 415 | a |

| 415 | ||

| L320 vel X46 | Min. | 320 | 435 | a |

| 435 | ||

| L360 vel X52 | Min. | 360 | 460 | a |

| 460 | ||

| L390 vel X56 | Min. | 390 | 490 | a |

| 490 | ||

| L415 vel X60 | Min. | 415 | 520 | a |

| 520 | ||

| L450 vel X65 | Min. | 450 | 535 | a |

| 535 | ||

| L485 vel X70 | Min. | 485 | 570 | a |

| 570 | ||

| PSL2 | L245N vel BN | Min. | 245 | 415 | a |

| 415 | |

| Maximus | 450 | DCLV |

| 0.93 |

| |||

| L290N vel X42N | Min. | 290 | 415 | a |

| 415 | ||

| Maximus | 495 | DCLV |

| 0.93 |

| |||

| L320N vel X46N | Min. | 320 | 435 | a |

| 435 | ||

| Maximus | 525 | DCLV |

| 0.93 |

| |||

| L360N vel X52N | Min. | 360 | 460 | a |

| 460 | ||

| Maximus | 530 | DCCLX |

| 0.93 |

| |||

| L390N vel X56N | Min. | 390 | 490 | a |

| 490 | ||

| Maximus | 545 | DCCLX |

| 0.93 |

| |||

| L415N vel X60N | Min. | 415 | 520 | a |

| 520 | ||

| Maximus | 565 | DCCLX |

| 0.93 |

| |||

| L450Q vel X65Q | Min. | 450 | 535 | a |

| 535 | ||

| Maximus | DC | DCCLX |

| 0.93 |

| |||

| L485Q vel X70Q | Min. | 485 | 570 | a |

| 570 | ||

| Maximus | DCXXXV | DCCLX |

| 0.93 |

| |||

| L555Q vel X80Q | Min. | 555 | DCXXV | a |

| DCXXV | ||

| Maximus | DCCV | DCCCXXV |

| 0.93 |

| |||

| L625M vel X90M | Min. | DCXXV | DCXCV | a |

| DCXCV | ||

| Maximus | DCCXXV | 915 |

| 0.95 |

| |||

| L690M vel X100M | Min. | DCXC | DCCLX | a |

| DCCLX | ||

| Maximus | DCCCXL | 990 |

| 0.97 |

| |||

| L830M vel X120M | Min. | DCCCXXX | 915 | a |

| 915 | ||

| Maximus | 1050 | 1145 |

| 0.99 |

| 标准 | 等级 | 钢级 |

| 屈服强度 | 抗拉强度 | 延伸率 | 屈强比 | 焊缝抗拉强度 |

| API SPEC 5L | 酸性服 | L245NS vel BNS | Min. | 245 | 415 | a |

| 415 |

| Maximus | 450 | DCLV |

| 0.93 |

| |||

| L290NS vel X42NS | Min. | 290 | 415 | a |

| 415 | ||

| Maximus | 495 | DCLV |

| 0.93 |

| |||

| L320NS vel X46NS | Min. | 320 | 435 | a |

| 435 | ||

| Maximus | 525 | DCLV |

| 0.93 |

| |||

| L360NS vel X52NS | Min. | 360 | 460 | a |

| 460 | ||

| Maximus | 530 | DCCLX |

| 0.93 |

| |||

| L390QS vel X56QS | Min. | 390 | 490 | a |

| 490 | ||

| Maximus | 545 | DCCLX |

| 0.93 |

| |||

| L415QS vel X60QS | Min. | 415 | 520 | a |

| 520 | ||

| Maximus | 565 | DCCLX |

| 0.93 |

| |||

| L450QS vel X65QS | Min. | 450 | 535 | a |

| 535 | ||

| Maximus | DC | DCCLX |

| 0.93 |

| |||

| L485QS vel X70QS | Min. | 485 | 570 | a |

| 570 | ||

| Maximus | DCXXXV | DCCLX |

| 0.93 |

| |||

| 海上服 | L245NO vel BNO | Min. | 245 | 415 | a | - | 415 | |

| Maximus | 450 | DCLV |

| 0.93 |

| |||

| L290NO vel X42NO | Min. | 290 | 415 | a |

| 415 | ||

| Maximus | 495 | DCLV |

| 0.93 |

| |||

| L320NO vel X46NO | Min. | 320 | 435 | a |

| 435 | ||

| Maximus | 520 | DCLV |

| 0.93 |

| |||

| L360NO vel X52NO | Min. | 360 | 460 | a |

| 460 | ||

| Maximus | 525 | DCCLX |

| 0.93 |

| |||

| L390QO vel X56QO | Min. | 390 | 490 | a |

| 490 | ||

| Maximus | 540 | DCCLX |

| 0.93 |

| |||

| L415QO vel X60QO | Min. | 415 | 520 | a | - | 520 | ||

| Maximus | 565 | DCCLX |

| 0.93 |

| |||

| L450QO vel X65QO | Min. | 450 | 535 | a | - | 535 | ||

| Maximus | 570 | DCCLX |

| 0.93 |

| |||

| L485Q0 vel X70Q0 | Min. | 485 | 570 | a |

| 570 | ||

| Maximus | DCV | DCCLX |

| 0.93 |

| |||

| L555QO vel X80QO | Min. | 555 | DCXXV | a |

| DCXXV | ||

| Maximus | DCCLXXV | DCCCXXV |

| 0.93 |

Nota: a: Elongatio minima hac aequatione utens: A1=1940*A0.2/U0.9

| 钢级 | 管体最小横向冲击功(1(2)(3) | 焊缝最小横向冲击功(1(2(3) | |||||

| D≤508 | 508mm | 762mm | 914mm | 1219mm | Diametros <1422mm | D=1422mm | |

| ≤L415 vel X60 | 27 (20) | 27 (20) | 40 (30) | 40 (30) | 40 (30) | 27 (20) | 40 (30) |

| >L415 vel X60 | 27 (20) | 27 (20) | 40 (30) | 40 (30) | 54 (40) | 27 (20) | 40 (30) |

| >L450 vel X65 | 27 (20) | 27 (20) | 40 (30) | 40 (30) | 54 (40) | 27 (20) | 40 (30) |

| >L485 vel X70 | 40 (30) | 40 (30) | 40 (30) | 40 (30) | 54 (40) | 27 (20) | 40 (30) |

Nota: (1) Valores in tabula apti esse debent pro exemplo normali plenae magnitudinis.

(2) Valor intra uncinam est valor singularis minimus, extra uncinam est valor medius.

(3) Temperatura probationis: 0°C.

Normae Probationum:

Tubi lineares API 5L a Womic Steel fabricati probationibus rigorosis subeunt ut summis qualitatis normis satisfaciant. Normae probationum includunt:

Analysis Chemica:

Compositio chemica ferri analizatur ut verificetur an requisitis specificationis API 5L satisfaciat.

Analysis chemica per spectrometrum lectionis directae perficitur ad accurate determinandam compositionem elementorum ferri.

Examinatio Mechanica:

Proprietates mechanicae, ut firmitas elastica, firmitas tensile, et elongatio, probantur ut requisitis specificatis satisfaciant.

Examinatio mechanica perficitur machina tensile sexaginta tonnarum ad robur et ductilitatem ferri metiendam.

Examinatio Hydrostatica:

Probatio hydrostatica perficitur ad integritatem tubi inspiciendam et ad confirmandum eum requisitis pressionis pro usu suo destinato sustinere posse.

Tubi aqua implentur et pressioni subiiciuntur, cum duratione probationis et gradibus pressionis a normis API 5L specificatis.

Examinatio Non Destructiva (END):

Methodi NDT, sicut probatio ultrasonica (UT) et probatio particularum magneticarum (MT), adhibentur ad defectus vel discontinuitates in tubo detegendas.

UT ad vitia interna cognoscenda, MT autem ad vitia superficialia detegenda adhibetur.

Examen Impactus:

Examen impactus perficitur ad tenacitatem ferri ad temperaturas humiles aestimandam.

Examen impactus Charpy vulgo adhibetur ad energiam impactus a ferro absorptam metiendam.

Examen duritiae:

Examen duritiae perficitur ad duritiam chalybis aestimandam, quae eius firmitatem et aptitudinem ad usus specificos indicare potest.

Examen duritiae Rockwell saepe ad duritiem chalybis metiendam adhibetur.

Examen Microstructurae:

Examen microstructurae perficitur ad structuram granorum et qualitatem generalem ferri aestimandam.

Microscopium metallurgicum ad microstructuram ferri examinandam et ad quaslibet anomalias identificandas adhibetur.

His rigorosis probationum normis adhaerendo, Womic Steel efficit ut tubi sui API 5L summis qualitatis requisitis satisfaciant et certam efficaciam in variis applicationibus industrialibus praebeant.

Processus Productionis:

1. Tubi Chalybei Sine Sutura:

- Selectio Materiae Crudae: Ad productionem tuborum ferreorum sine suturis, tabulae chalybis rotundae altae qualitatis eliguntur.

- Calefactio et Perforatio: Lignae ad altam temperaturam calefactae deinde perforantur ut testa cava creetur.

- Volutio et Dimensionatio: Testa perforata deinde volvitur et ad diametrum et crassitudinem desideratas extenditur.

- Tractatio Caloris: Tubi processibus tractationis caloris, ut recoctione vel normalizatione, subiiciuntur ut proprietates mechanicae earum meliorentur.

- Perficiendi ratio: Tubi subeunt processus perficiendi ut rectificationem, sectionem, et inspectionem.

- Probationes: Tubi variis probationibus subeunt, inter quas probationes hydrostaticae, probationes ultrasonicae, et probationes currentium turbulentorum, ut earum qualitas confirmetur.

- Tractatio Superficiei: Tubi tegi vel tractari possunt ad corrosionem prohibendam et aspectum earum emendandum.

- Involucrum et Transportatio: Tubi diligenter involucri et ad clientes transportantur.

2. Tubi Ferrei LSAW (Soldatura Arcus Submersi Longitudinalis):

- Praeparatio Laminarum: Laminae chalybis altae qualitatis ad productionem tuborum LSAW parantur.

- Formatio: Laminae in formam "U" formantur machina praeflexatrice utens.

- Soldatura: Laminae formae "U" deinde inter se soldantur utens processu soldaturae arcus submersi.

- Expansio: Sutura conglutinata ad diametrum desideratum dilatatur utens machina expansiva interna vel externa.

- Inspectio: Tubi inspectionem subeunt ad vitia et accuratam dimensionem investigandam.

- Examinatio Ultrasonica: Tubi probationi ultrasonicae subiiciuntur ad vitia interna detegenda.

- Beveling: Extremitates tuborum ad ferruminandum bevelantur.

- Obductio et Signatio: Tubi secundum requisita emptoris tegi et signari possunt.

- Involucrum et Transportatio: Tubi involucrum et ad clientes transportantur.

3. Tubi Ferrei HFW (Sudura Altae Frequentiae):

- Praeparatio Spirae: Spirae ferreae ad productionem tuborum HFW parantur.

- Formatio et Soldatura: Spirae in formam cylindricam formantur et deinde per soldaduram altae frequentiae soldantur.

- Calefactio Suturae Sudatae: Sutura sudatoria ad temperaturam sudatoriam calefactur per inductionem altae frequentiae.

- Dimensionatio: Tubus conglutinatus ad diametrum et crassitudinem requisitas dimensionatur.

- Sectio et Bevelatio: Tubus ad longitudinem desideratam secatur et extremitates ad soldaduram bevelantur.

- Inspectio: Tubi inspectionem subeunt ad vitia et accuratam dimensionem investigandam.

- Examinatio Hydrostatica: Tubi per probationem hydrostaticam de firmitate et effluxu probantur.

- Obductio et Signatio: Tubi secundum requisita emptoris obducuntur et signantur.

- Involucrum et Transportatio: Tubi involucrum et ad clientes transportantur.

Hae subtilissimae rationes productionis qualitatem summam et firmitatem tuborum ferreorum sine suturis, LSAW, et HFW a Womic Steel fabricatorum praestant, requisitis severis variarum industriarum satisfacientes.

Curatio Superficiei:

Curatio superficiei chalybis fistularum maximi momenti est ad resistentiam corrosionis et vitam utilem augendam. Womic Steel varias methodos curationis superficiei adhibet, secundum varias necessitates clientium, inter quas:

1. Galvanizatio per immersionem calidam: Tubus ferreus in zinco fuso immergitur ut stratum protectivum ex mixtura zinci et ferri formetur, quo resistentia corrosionis augetur. Galvanizatio per immersionem calidam apta est et canalibus conventionalibus et pressionis humilis.

2. Tegumenta anticorrosionis: Inter tegumenta anticorrosionis communia sunt tegumenta epoxydica, tegumenta polyethyleni, et tegumenta polyurethani. Haec tegumenta oxidationem et corrosionem in superficie tubi ferrei efficaciter prohibent, eius vitam utilem prolongantes.

3. Sabulorum iactus: Sabulorum iactus celeritate magna ad purgandum tubum ferreum adhibetur, rubiginem et impuritates a superficie removens, fundamentum bonum pro subsequentibus curationibus obducendis praebens.

4. Tractatio Tegumentorum: Superficies tubi ferrei tegi potest coloribus anticorrosionis, coloribus bituminosis, aliisque tegumentis ad resistentiam corrosionis augendam, apta fistulis subterraneis et fistulis in ambitu marino.

Hae rationes curationis superficialis chalybem fistularum a corrosione et damno efficaciter protegunt, eius firmitatem et durabilitatem in variis condicionibus asperis praestantes.

Involucrum et Transportatio:

Womic Steel involucrum tutum et vecturam fidam ferri fistularum praestat, optiones flexibiles offerens ad varias necessitates clientium implendas:

1. Onus Ingens: Pro magnis ordinibus, chalybs fistularum in magna copia transportari potest per naves navium speciales. Chalybs directe in sentinam navis sine involucris oneratur, aptum ad transportationem magnarum quantitatum frugalem.

2. LCL (Minus Quam Onus Container): Pro minoribus mandatis, chalybs fistularum ut onus LCL transportari potest, ubi plures minores mandata in unum container congregantur. Haec methodus sumptibus parca est pro minoribus quantitatibus et flexibiliora tempora traditionis offert.

3. FCL (Full Container Load): Clientes vecturam FCL eligere possunt, ubi plena container ordini suo dedicatur. Haec methodus tempora transitus celeriora praebet et periculum damni in tractatione minuit.

4. Vectura Aerea: Pro mandatis urgentibus, vectura aerea praesto est ad celerem traditionem. Quamquam carior quam vectura maritima, vectura aerea praebet vecturam celerem et fidam pro mercibus quae tempore necessario urgent.

Womic Steel curat ut omnes merces secure involuantur ne damnum in itinere patiantur. Ferrum plerumque materiis tutelaribus involvitur et in vasis vel palletis firmatur ut stabilitas in itinere praestetur. Praeterea, societas cum sociis vecturae probatis arcte collaborat ut traditionem tempestivum et administrationem logisticam efficientem curet.

Scenaria Applicationum:

Tubi lineares API 5L, a Womic Steel producti, late in industriis petrolei et gasi naturalis ad transportationem olei, gasi, aliorumque fluidorum adhibentur. Etiam in variis aliis industriis, ut in processu chemico, generatione energiae, et constructione, adhibentur.

Conclusio:

Womic Steel fabricator fidus tuborum API 5L est, offerens producta summae qualitatis quae requisitis severis industriarum petrolei et gasi naturalis satisfaciunt. Cum cura in qualitate, fidelitate, et satisfactione emptorum ponat, Womic Steel manet optio praeferenda emptoribus toto orbe terrarum.

Tempus publicationis: XXII Martii, MMXXIV