Descriptio Producti

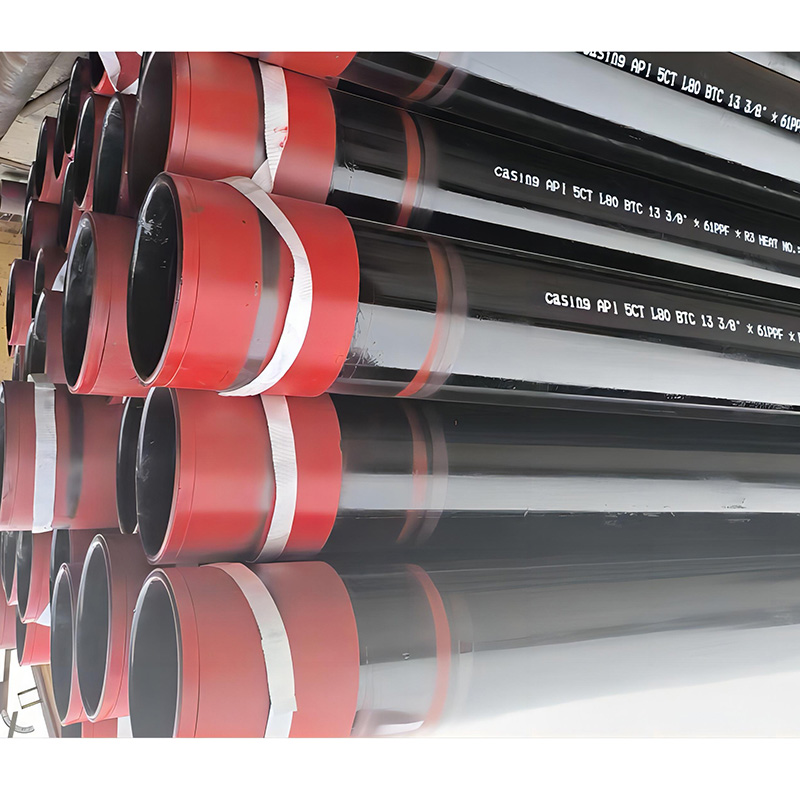

Tubi et involucri late ad petroleum et gasium excolendum adhibentur. Partes essentiales in industria petrolei et gasii sunt, quae ad extractionem et translationem hydrocarbonum (olei et gasii naturalis) e receptaculis subterraneis ad superficiem adhibentur. Munera gravissima agunt in securitate, integritate, et efficacia operationum perforationis et productionis curanda.

Tubus est genus fistulae adhibitae ad transferendum oleum crudum et gas naturale e strato olei vel gasis ad terram postquam perforatio perfecta est. Tubus pressionem generatam in processu extractionis permittere potest. Tubus eodem modo ac involucrum fabricatur, sed processus qui "evertere" appellatur etiam requiritur ad crassitudinem tubi.

Tubus ad protegenda foramina quae in terram effossa sunt propter oleum adhibetur. Similiter ac fistula perforatoria adhibita, fistulae involucri puteorum olei etiam pressionem tensionis axialis permittunt, itaque chalybs altae qualitatis et altae firmitatis requiritur. Tubi involucri OCTG sunt fistulae magni diametri quae in foramen cementantur.

Specificationes

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| API 5CT: J55, K55, N80, L80, P110 |

| API 5D: E75, X95, G105, S135 |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A106: GR.A, GR.B, GR.C |

| ASTM A53/A53M: GR.A, GR.B |

| ASTM A335: P1, P2, 95, P9, P11, P22, P23, P91, P92, P122 |

| ASTM A333: Gradus 1, Gradus 3, Gradus 4, Gradus 6, Gradus 7, Gradus 8, Gradus 9, Gradus 10, Gradus 11 |

| DIN 2391: St30Al, St30Si, St35, St45, St52 |

| DIN EN 10216-1: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| JIS G3454: STPG 370, STPG 410 |

| JIS G3456: STPT 370, STPT 410, STPT 480 |

| GB/T 8163: 10#, 20#, Q345 |

| GB/T 8162: 10#, 20#, 35#, 45#, Q345 |

Index Involucrorum Ferreorum ISO/API

| Inscriptionesa | Extra diameter D mm | Nominalis linearis massab, c Conditiones et stipulationes kg/m² | Murus crassitudo t mm | Genus finis-finitionis | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 Typus 1, Q | C90 T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| Quattuor et dimidium Quattuor et dimidium Quattuor et dimidium Quattuor et dimidium Quattuor et dimidium | 9.50 10.50 11.60 13.50 15.10 | 114,30 114,30 114,30 114,30 114,30 | 14,14 15,63 17, 26 20,09 22,47 | 5,21 5,69 6,35 7,37 8,56 | PS — — — — | PS PSB PSLB — — | PS PSB PLB PLB — | — — PLB PLB — | — — PLB PLB — | — — PLB PLB — | — — PLB PLB PLB | — — — — PLB |

| 5 5 5 5 5 5 5 | 11.50 hora tredecim 15.00 hora XVIII 21.40 XXIII.XX XXIV.X | 127,00 127,00 127,00 127,00 127,00 127,00 127,00 | 17,11 19,35 22,32 XXVI, LXXIX 31,85 34,53 35,86 | 5,59 6,43 7,52 9,19 11,10 12,14 12,70 | — — — — — — — | PS PSLB PSLBE — — — — | PS PSLB PLB PLB PLB — — | — — PLBE PLBE PLB PLB PLB | — — PLBE PLBE PLB PLB PLB | — — PLBE PLBE PLB PLB PLB | — — PLBE PLBE PLB PLB PLB | — — — PLBE PLB PLB PLB |

| Quinque et dimidium Quinque et dimidium Quinque et dimidium Quinque et dimidium Quinque et dimidium Quinque et dimidium Quinque et dimidium Quinque et dimidium Quinque et dimidium Quinque et dimidium Quinque et dimidium Quinque et dimidium | hora quarta decima 15.50 Hora septima decima XX.00 23.00 26.80 29.70 32.60 35.30 38.00 40.50 43.10 | 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 | 20,83 XXIII,VII 25,30 29,76 34,23 39,88 44,20 48,51 52,53 56,55 60,27 64,14 | 6,20 6,98 7,72 9,17 10,54 12,70 14,27 15,88 17,45 19,05 20,62 XXII, XXII | PS | PS PSLBE PSLBE | PS PSLB PLB PLB PLB | — — PLBE PLBE PLBE — — — — — — — | PLBE PLBE PLBE | PLBE PLBE PLBE P P P P P P P | PLBE PLBE PLBE | — — — — PLBE — — — — — — |

| 6-5/8 6-5/8 6-5/8 6-5/8 | XX.00 24.00 XXVIII.00 32.00 | 168,28 168,28 168,28 168,28 | 29,76 35,72 41,67 47,62 | 7,32 8,94 10,59 12,06 | PS — — | PSLB PSLBE — | PSLB PLB PLB — | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — — PLBE |

| 7 7 7 7 7 7 7 7 7 7 7 7 7 | Hora septima decima XX.00 23.00 26.00 29.00 32.00 35.00 38.00 42.70 46.40 50.10 53.60 57.10 | 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 | 25,30 29,76 34,23 38,69 43,16 47,62 52,09 56,55 63,54 69,05 74,56 79,77 84,97 | 5,87 6,91 8,05 9,19 10,36 11,51 12,65 13,72 15,88 17,45 19,05 20,62 XXII, XXII | PS PS — — — — — — — — — — — | — PS PSLBE PSLBE — — — — — — — — — | — PS PLB PLB PLB PLB — — — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE P P P P P | — — — PLBE PLBE PLBE PLBE PLBE — — — — — | — — — — — — PLBE PLBE — — — — — |

| Vide notas ad finem tabulae. | ||||||||||||

| Inscriptionesa | Extra diameter D mm | Nominalis linearis massab, c Conditiones et stipulationes kg/m² | Murus crassitudo t mm | Genus finis-finitionis | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 Typus 1, Q | C90 T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| Septem et quinque octavae Septem et quinque octavae Septem et quinque octavae Septem et quinque octavae Septem et quinque octavae Septem et quinque octavae Septem et quinque octavae Septem et quinque octavae Septem et quinque octavae Septem et quinque octavae | 24.00 XXVI.XL 29.70 33.70 39.00 42.80 45.30 47.10 51.20 55.30 | 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 | 35,72 39,29 44,20 50,15 58,04 63,69 67,41 70,09 76,19 82,30 | 7,62 8,33 9,52 10,92 12,70 14,27 15,11 15,88 17,45 19,05 | PS | PSLBE | PSLB PLB PLB | PLBE PLBE PLBE PLBE PLB PLB PLB | PLBE PLBE PLBE PLBE PLB PLB PLB | PLBE PLBE PLBE PLBE PLB PLB PLB P P | PLBE PLBE PLBE PLB PLB PLB | PLBE PLB PLB PLB |

| Septem et tres quartae partes | 46.10 | 19,685 | 6,860 | 1511 | — | — | — | P | P | P | P | P |

| 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 | 24.00 XXVIII.00 32.00 36.00 40.00 44.00 49.00 | 219,08 219,08 219,08 219,08 219,08 219,08 219,08 | 35,72 41,67 47,62 53,57 59,53 65,48 72,92 | 6,71 7,72 8,94 10,16 11,43 12,70 14,15 | PS PS — — — — | PS — PSLBE PSLBE — — — | PS PS PSLB PSLB PLB — — | — — — PLBE PLBE PLBE PLBE | — — — PLBE PLBE PLBE PLBE | — — — PLBE PLBE PLBE PLBE | — — — — PLBE PLBE PLBE | — — — — — — PLBE |

| 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 | 32.30 36.00 40.00 43.50 47.00 53.50 58.40 59.40 64.90 70.30 75.60 | 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 | 48,07 53,57 59,53 64,73 69,94 79,62 86,91 88,40 96,58 104,62 112,50 | 7,92 8,94 10,03 11,05 11,99 13,84 15,11 15,47 17,07 18,64 20,24 | PS PS — — — — — — — — — | — PSLB PSLBE — — — — — — — — | — PSLB PSLB PLB PLB — — — — — — | — — PLBE PLBE PLBE PLBE PLB — — — — | — — PLBE PLBE PLBE PLBE PLB — — — — | — — PLBE PLBE PLBE PLBE PLB P P P P | — — — PLBE PLBE PLBE PLB — — — — | — — — — PLBE PLBE PLB — — — — |

| Decem et tres quartae partes Decem et tres quartae partes Decem et tres quartae partes Decem et tres quartae partes Decem et tres quartae partes Decem et tres quartae partes Decem et tres quartae partes Decem et tres quartae partes Decem et tres quartae partes Decem et tres quartae partes | 32.75 40.50 45.50 51.00 55.50 60.70 65.70 73.20 79.20 85.30 | 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 | 48,74 60,27 67,71 75,90 82,59 90,33 97,77 108,93 117,86 126,94 | 7,09 8,89 10,16 11,43 12,57 13,84 15,11 17,07 18,64 20,24 | PS PS | PSB PSBE PSBE | PSB PSB PSB PSB | PSBE PSBE | PSBE PSBE | PSBE PSBE PSBE PSB P P P | PSBE PSBE PSBE PSB | PSBE PSB |

| 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 | 42.00 47.00 54.00 60.00 65.00 71.00 | 298,45 298,45 298,45 298,45 298,45 298,45 | 62,50 69,94 80,36 89,29 96,73 105,66 | 8,46 9,53 11,05 12,42 13,56 14,78 | PS — — — | PSB PSB PSB — — | PSB PSB PSB — — | — — PSB P P | — — PSB P P | — — PSB P P | — — PSB P P | — — PSB P P |

| 13-3/8 13-3/8 13-3/8 13-3/8 13-3/8 | 48.00 54.50 61.00 68.00 72.00 | 339,72 339,72 339,72 339,72 339,72 | 71,43 81,10 90,78 101,19 107,15 | 8,38 9,65 10,92 12,19 13,06 | PS — — — — | — PSB PSB PSB — | — PSB PSB PSB — | — — — PSB PSB | — — — PSB PSB | — — — PSB PSB | — — — PSB PSB | — — — — PSB |

| Vide notas ad finem tabulae. | ||||||||||||

| Inscriptionesa | Extra diameter D mm | Nominalis linearis massab, c Conditiones et stipulationes kg/m² | Murus crassitudo t mm | Genus finis-finitionis | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 Typus 1, Q | C90 T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 16 16 16 16 | 65.00 75.00 84.00 109.00 | 406,40 406,40 406,40 406,40 | 96,73 111,61 125,01 162,21 | 9,53 11,13 12,57 16,66 | PS | PSB PSB P | PSB PSB | P | P | P | P | |

| 18-5/8 | 87.50 | 47,308 | 13,021 | 1105 | PS | PSB | PSB | — | — | — | — | — |

| 20 20 20 | 94.00 106.50 133.00 | 508,00 508,00 508,00 | 139,89 158,49 197,93 | 11,13 12,70 16,13 | PSL — — | PSLB PSLB PSLB | PSLB PSLB — | — — — | — — — | — — — | — — — | — — — |

| P = Extremum planum, S = Filum rotundum breve, L = Filum rotundum longum, B = Filum contrafulcimenti, E = Linea extrema. | ||||||||||||

| ♦ Etiquettae ad informationem et auxilium in ordinando sunt. ♦ Massae lineares nominales, filetatae et copulatae (columna 2) ad informationem tantum monstrantur. ♦ Densitates chalybum chromaticorum martensiticorum (typi L80 9Cr et 13Cr) a chalybibus carbonicis differunt. Massae ergo monstratae non sunt accuratae pro chalybibus chromaticis martensiticis. Factor correctionis massae 0,989 adhiberi potest. | ||||||||||||

| Inscriptiones | Diameter externus D mm | Linearis simplex massa kg/m² | Crassitudo parietis t mm | |

| 1 | 2 | |||

| 1 | 2 | 3 | 4 | 5 |

| Tres et dimidium 4 Quattuor et dimidium 5 Quinque et dimidium 6-5/8 | 9.92 11.35 13.05 17.95 19.83 27.66 | 88,90 101,60 114,30 127,00 139,70 168,28 | 14,76 16,89 19,42 XXVI, LXXI 29,51 41,18 | 7,34 7,26 7,37 9,19 9,17 10,59 |

Index Tuborum Ferreorum ISO/API

| Inscriptiones | Extra diameter D mm | Nominalis linearis massaea, b | Murus crassus- ness t mm | Genus finis extremic | |||||||||||

| Non- perturbatus Conditiones et stipulationes kg/m² | Ext. perturbatus Conditiones et stipulationes kg/m² | Integ. iunctura kg/m² | |||||||||||||

| 1 | 2 | ||||||||||||||

| NU Conditiones et stipulationes | EU Conditiones et stipulationes | IJ | H40 | J55 | L80 | N80 Typus 1, Q | C90 | T95 | P110 | ||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1.900 1.900 1.900 1.900 1.900 | 2.40 2.75 3.65 4.42 5.15 | — 2.90 3.73 — — | 2.40 2.76 — — — | 48,26 48,26 48,26 48,26 48,26 | — 4,09 5,43 6,58 7,66 | — 4,32 5,55 — — | 3,57 4,11 — — — | 3,18 3,68 5,08 6,35 7,62 | PI PNUI PU — — | PI PNUI PU — — | — PNUI PU P P | — PNUI PU — — | — PNUI PU P P | — PNUI PU P P | PU — — |

| 2.063 2.063 | 3.24 4.50 | — — | 3.25 — | 52,40 52,40 | — — | — — | 4,84 — | 3,96 5,72 | PI P | PI P | PI P | PI P | PI P | PI P | P |

| 2-3/8 2-3/8 2-3/8 2-3/8 2-3/8 | 4.00 4.60 5.80 6.60 7.35 | 4.70 5.95 7.45 | 60,32 60,32 60,32 60,32 60,32 | 5,95 6,85 8,63 9,82 10,94 | 6,99 8,85 11,09 | 4,24 4,83 6,45 7,49 8,53 | PN PNU | PN PNU | PN PNU PNU P PU | PN PNU PNU — — | PN PNU PNU P PU | PN PNU PNU P PU | PNU PNU | ||

| 2-7/8 2-7/8 2-7/8 2-7/8 | 6.40 7.80 8.60 9.35 | 6.50 7.90 8.70 9.45 | — — — | 73,02 73,02 73,02 73,02 | 9,52 11,61 12,80 13,91 | 9,67 11,76 12,95 14,06 | — — — | 5,51 7,01 7,82 8,64 | PNU — — | PNU — — | PNU PNU PNU PU | PNU PNU PNU — | PNU PNU PNU PU | PNU PNU PNU PU | PNU PNU PNU — |

| 2-7/8 2-7/8 | 10.50 11.50 | — | — | 73,02 73,02 | 15,63 17,11 | — | — | 9,96 11,18 | — | — | P P | — | P P | P P | — |

| Tres et dimidium Tres et dimidium Tres et dimidium Tres et dimidium Tres et dimidium Tres et dimidium Tres et dimidium | 7.70 9.20 10.20 12.70 14.30 15.50 Hora septima decima | — 9.30 — 12.95 — — — | — — — — — — — | 88,90 88,90 88,90 88,90 88,90 88,90 88,90 | 11,46 13,69 15,18 18,90 21,28 XXIII,VII 25,30 | — 13,84 — 19,27 — — — | — — — — — — — | 5,49 6,45 7,34 9,52 10,92 12,09 13,46 | PN PNU PN — — — — | PN PNU PN — — — — | PN PNU PN PNU P P P | PN PNU PN PNU — — — | PN PNU PN PNU P P P | PN PNU PN PNU P P P | — PNU — PNU — — — |

| 4 4 4 4 4 4 | 9.50 10.70 13.20 16.10 18.90 XXII.XX | — Hora undecima — — — — | — — — — — — | 101,60 101,60 101,60 101,60 101,60 101,60 | 14,14 — 19,64 23,96 28,13 33,04 | — XVI, XXXVII — — — — | — — — — — — | 5,74 6,65 8,38 10,54 12,70 15,49 | PN PU — — — — | PN PU — — — — | PN PU P P P P | PN PU — — — — | PN PU P P P P | PN PU P P P P | — — — — — — |

| Quattuor et dimidium Quattuor et dimidium Quattuor et dimidium Quattuor et dimidium Quattuor et dimidium Quattuor et dimidium Quattuor et dimidium | 12.60 15.20 Hora septima decima 18.90 21.50 23.70 XXVI.X | 12.75 | 114,30 114,30 114,30 114,30 114,30 114,30 114,30 | 18,75 22,62 25,30 28,13 32,00 35,27 38,84 | 18,97 | 6,88 8,56 9,65 10,92 12,70 14,22 16,00 | PNU | PNU | PNU P P P P P P | PNU — — — — — — | PNU P P P P P P | PNU P P P P P P | |||

| P = Extremum planum, N = Fileta non perturbata et copulata, U = Fileta externa perturbata et copulata, I = Iunctura integra. | |||||||||||||||

| ♦ Massae lineares nominales, fila et copulae (columnae 2, 3, 4) ad informationem tantum monstrantur. ♦ Densitates chalybum chromaticorum martensiticorum (typi L80 9Cr et 13Cr) a chalybibus carbonicis differunt. Massae ergo monstratae non sunt accuratae pro chalybibus chromaticis martensiticis. Factor correctionis massae 0,989 adhiberi potest. ♦ Tubi non perturbati cum copulationibus regularibus vel copulationibus specialibus conicis praesto sunt. Tubi perturbati externe cum copulationibus regularibus, conicis specialibus, vel cum amplitudine speciali praesto sunt. | |||||||||||||||

Norma et Gradus

Gradus Standard Tuborum et Involucrorum:

API 5CT J55, K55, L80, N80, P110, C90, T95, H40

Extremitates tuborum et involucrorum API 5CT:

(STC) Involucrum breve filum rotundum

(LC) Involucrum filum rotundum longum

(BC) Involucrum filum fulcri

(XC) Involucrum lineae extremae

(NU) Tubus non perturbatus

(EU) Tubus externus perturbatus

(IJ) Tubus iuncturae integrae

Involucrum et tubi secundum supradicta conexiones cum norma API5CT / API Standards tradendi sunt.

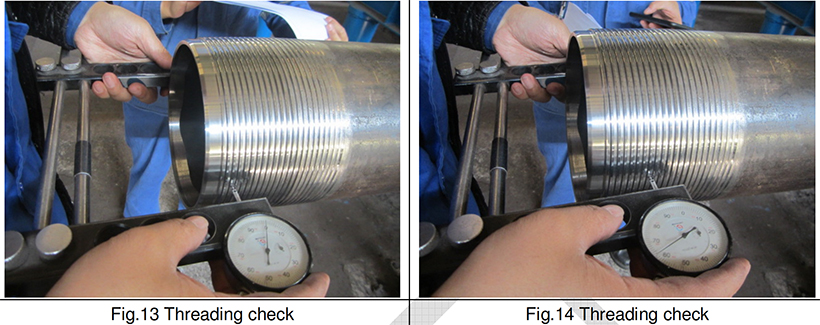

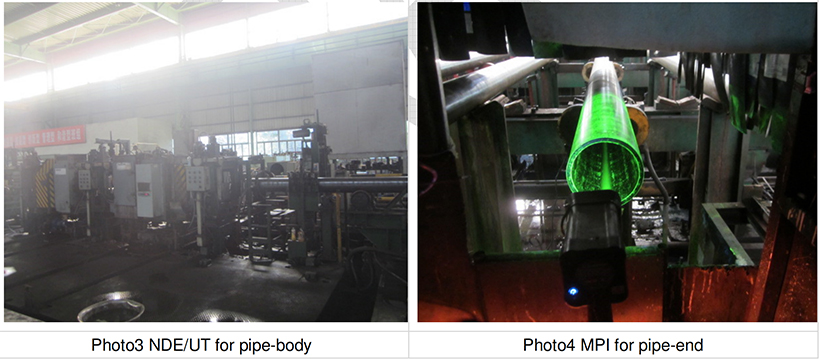

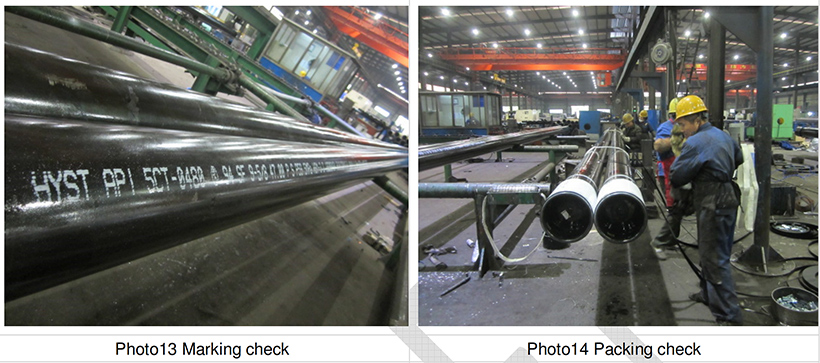

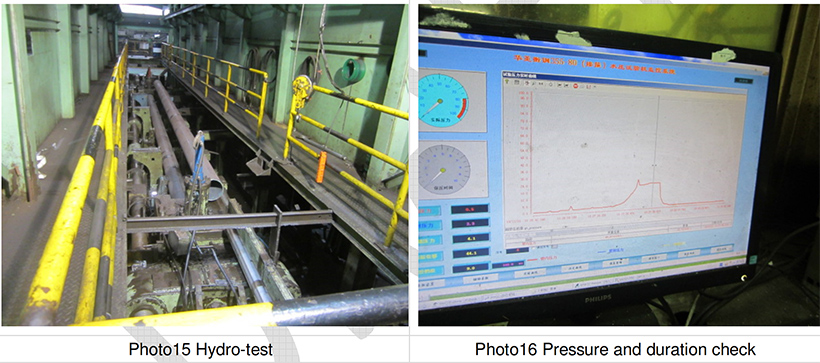

Qualitatis Moderatio

Inspectio Materiae Rudis, Analysis Chemica, Examen Mechanica, Inspectio Visualis, Examen Tensionis, Examen Dimensionis, Examen Flexionis, Examen Planificationis, Examen Impactus, Examen DWT, Examen NDT, Examen Hydrostaticum, Examen Duritudinis…..

Notatio, pictura ante traditionem.

Sarcina et Transportatio

Modus sarcinandi tuborum ferreorum purgationem, congregationem, involucrum, fasciculationem, firmationem, inscriptionem, palettationem (si opus est), receptacula, reponendum, obsignationem, transportationem, et disarcionem complectitur. Genera varia tuborum ferreorum et iuncturae cum variis modis sarcinandi. Hic processus comprehensivus efficit ut tubi ferrei transportentur et ad destinationem suam in optima condicione perveniant, ad usum destinatum parati.

Usus et Applicatio

Tubi ferrei quasi spina dorsalis modernae artis industrialis et civilis funguntur, amplam varietatem applicationum sustinentes quae ad progressionem societatum et oeconomiarum toto orbe conferunt.

Tubi et accessiones ferreae, quas Womic Steel producimus, late adhibitae sunt ad fistulas petrolei, gasii, cibustibilis et aquae, opera extra litus/terra, portuum maritimorum constructionis et aedificationis, dragationem, ferrum structurale, palos et pontium constructionis, necnon tubos ferreos accurati ad productionem cylindrorum transportatorum, et cetera...