Descriptio Producti

Tubus chalybis accurati est genus tubi chalybis carbonis, chalybis mixti, vel chalybis inoxidabilis, magnitudinibus altae praecisionis praeditus. Plerumque per processus laminationis calidae vel extractionis frigidae (laminationis frigidae) producuntur. Itaque tubi accurati sunt tubi sine suturis, quidam tubi accurati sunt tubi chalybis sudati.

Tubi accurati cum pluribus commodis designati:

● Superficies intus et extra nullo strato tegitur;

● Tubi praecisionis pressionem magnam ferre possunt, nulla stillantia;

● Tolerantia severa minor;

● Superficies lenis

● Nulla reformatio in flexura frigida, nullae fissurae in probatione expansionis et probatione applanationis.

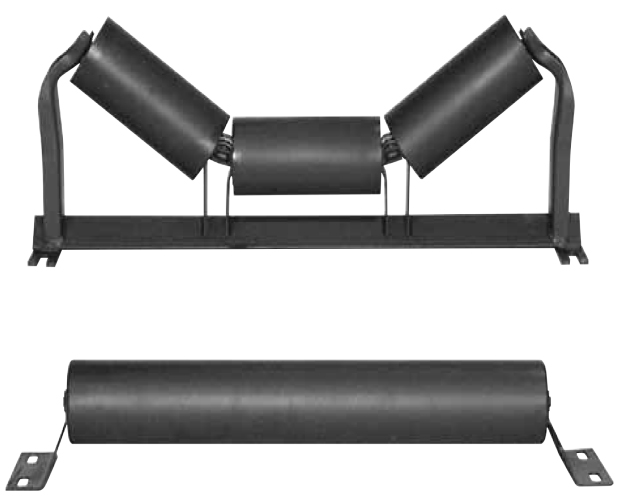

Tubi precisi late ad partes pneumaticas et componentes hydraulicas fabricandas adhibiti

Diameter internus et externus intra +/- 0.01 mm moderari potest. Ut et firmitas contra flexionem et firmitas torsionis eadem confirmentur, pondus tubi precisionis levius est. Late adhiberi potest in fabricatione partium machinarum precisionis et structurarum machinalium, et etiam vulgo adhibetur ad producenda varia genera armorum conventionalium, ut cannarum, proiectilium, ferculorum, cylindrorum transportatorum, molarum saccharariarum, et cetera.

Tubi et tubi ferrei summae praecisionis, quos produximus, late per multos annos apud fabricatores cylindrorum otiorum adhibiti sunt.

Magnopere gaudeo audire societatem vestram etiam in fabricatione cylindrorum otiosorum bene agere, cum multi alii clientes habeamus idem negotium quod vestra gerentes.

Tubi ferrei accurati a nobis producti, secundum varietatem et tolerantiam, infra scripta sunt:

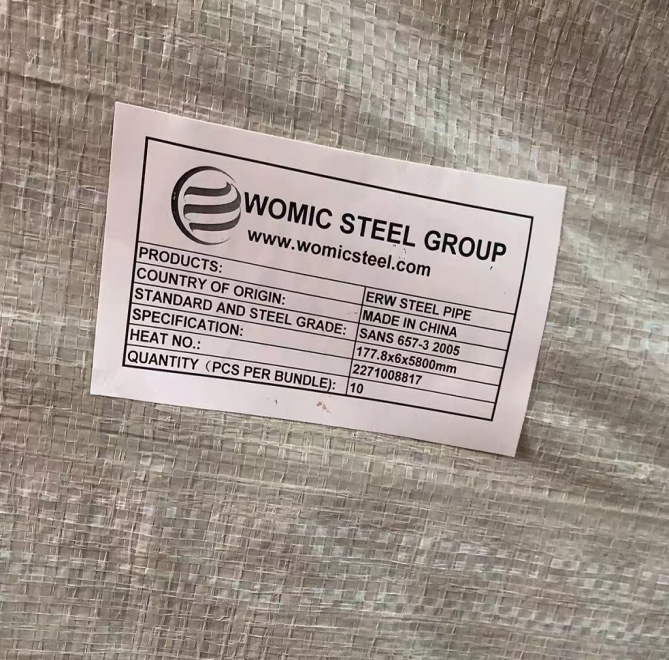

Diameter productionis regularis:101.6mm, 108mm, 127mm, 133.1mm, 152.4mm, 158.8mm, 165.1mm, 177.8mm, 219.1mm etc., etiam magnitudines ad mensuram factae praesto sunt.

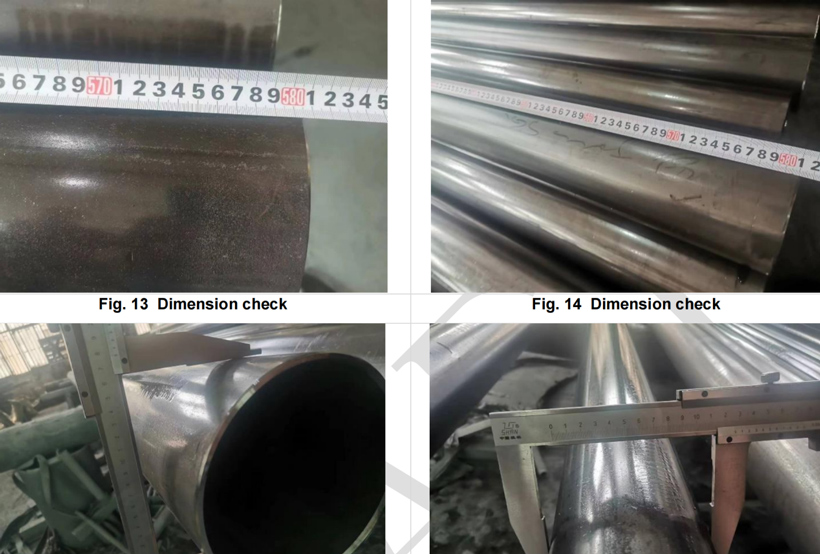

Moderatio tolerantiae:

Diametros exteriores 101.6mm ~ 127mm, secundum tolerantiam diametri exterioris specificatam ±0.1 mm, ovalitas 0.2 mm;

Diametros exteriores 133.1mm ~ 219.1mm, secundum tolerantiam diametri exterioris specificatam ±0.15mm, ovalitas 0.3 mm;

Crassitudo in pariete:

±0.1 mm pro crassitudine parietis tubi infra et 4.5 mm includens,

±0.1 mm pro crassitudine parietis tubi supra 4.5 mm.

Rectitudo:

Non excedere debet 1 in 1000 (mensuratum in medio tubi).

Tempus productionis plerumque viginti dies est. Responsionem tuam calidam et interrogationes exspecto, gratias ago.

Specificationes

| Scheda Specificationum Productionis Tuborum Chalybeorum Precisionis Womic Steel | |||||||||

| Tubus rotundus pro rotis et rotulis vecturae | Tubus OD mm | Tubus ID mm | Murus Th mm | Pondus kg/m² | SANS 657-3 | Tolerantia OD | Tolerantia Ponderis WT | Tolerantia Longitudinis | Ovalitas Maximus |

| 101.60 | 94.60 | 3.5 | 8.46 | Pars III | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 114.00 | 107.00 | 3.5 | 9.53 | Pars III | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 133.10 | 126.10 | 3.5 | 11.18 | Pars III | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 133.10 | 125.10 | 4.0 | 12.73 | Pars III | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 127.00 | 119.4 | 3.8 | 11.54 | Pars III | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 127.00 | 118.00 | 4.5 | 13.59 | Pars III | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 127.00 | 117.00 | 5.0 | 15.04 | Pars III | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 127.00 | 115.00 | 6.0 | 17.90 | Pars III | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 127.00 | 120.00 | 3.5 | 10.65 | Pars III | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 152.40 | 144.40 | 4.0 | 14.63 | Pars III | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 152.40 | 143.40 | 4.5 | 16.41 | Pars III | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 152.40 | 142.40 | 5.0 | 18.17 | Pars III | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 152.40 | 144.40 | 4.0 | 14.63 | Pars III | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 152.40 | 140.40 | 6.0 | 21.65 | Pars III | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 158.80 | 149.80 | 4.5 | 17.12 | Pars III | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 159.00 | 151.00 | 4.0 | 15.28 | Pars III | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 159.00 | 150.00 | 4.5 | 17.14 | Pars III | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 177.80 | 165.80 | 6.0 | 25.41 | Pars III | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 193.70 | 181.70 | 6.0 | 27.76 | Pars III | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 165.00 | 157.00 | 4.0 | 15.87 | Pars III | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 165.00 | 153.00 | 6.0 | 4.04 | Pars III | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 165.00 | 156.00 | 4.5 | 17.80 | Pars III | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 101.60 | 97.60 | 2.0 | 4.91 | -- | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 101.60 | 96.00 | 2.8 | 6.82 | -- | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 127.00 | 123.00 | 2.0 | 6.16 | -- | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 152.40 | 146.80 | 2.8 | 10.32 | -- | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| MATERIA STRUCTURALIS TUBI ROTUNDI | Tubus OD mm | Tubus ID mm | Murus Th mm | Pondus kg/m² | SANS 657-3 | Tolerantia OD | Tolerantia Ponderis WT | Ovalitas Maximus | |

| 31.80 | 25.80 | 3.0 | 2.13 | Pars Prima | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 48.40 | 42.40 | 3.0 | 3.36 | Pars Prima | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 63.50 | 57.50 | 3.0 | 4.47 | Pars Prima | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 76.20 | 69.20 | 3.5 | 6.27 | Pars Prima | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 76.20 | 67.20 | 4.5 | 7.95 | Pars Prima | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 88.90 | 84.90 | 2.0 | 4.28 | Pars Prima | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 88.90 | 82.90 | 3.0 | 6.35 | Pars Prima | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 88.90 | 81.90 | 3.5 | 7.37 | Pars Prima | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 88.90 | 78.90 | 5.0 | 10.34 | Pars Prima | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 101.60 | 95.60 | 3.0 | 7.29 | Pars Prima | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 101.60 | 92.60 | 4.5 | 10.77 | Pars Prima | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| Rectitudo non excedere debet 1mm in longitudine 1200mm (ad medium tubi punctum mensurata). | |||||||||

| MUNDUM, LIBER A SQUAM MOLENARIAM ET RUGIINE AUT ALIIS SUBSTANTIIS, UT OLEUM, ADIPE, ETC. | |||||||||

Norma et Gradus

SANS 657-3, Tubi praecisionis ad fabricationem cylindrorum transportatorum.

EN 10305-1, Tubi praecisionis pro permutatore caloris et condensatore.

DIN 2393, Tubi ferrei accuratius conglutinati, tubus ferreus systematis hydraulicalis

BS6323/4, Tubi accurati ad industriam electricam,

NF A 49-310, NF A 49-312, Tubi praecisionis ad machinas aedificatorias

UNI 7945, Tubi ferrei subtiliter sine suturis. Gradus ferri. Fe 280

STN/ČSN 42 6711, Tubi ferrei praecisionis sine suturis

STN/ČSN 42 6712, Tubi ferrei praecisionis sine suturis

PN-H 74240, PN-H 74220 Tubi Praecisionis Russici Standardis

ASTM A450 ad A519, Tubi Chalybis Praecisi ex Mixtione Ferritica / Mixtione Austentica

GOST 8734, 9567, 12132 Tubi ferrei accurati, frigidis et sine suturis, formati

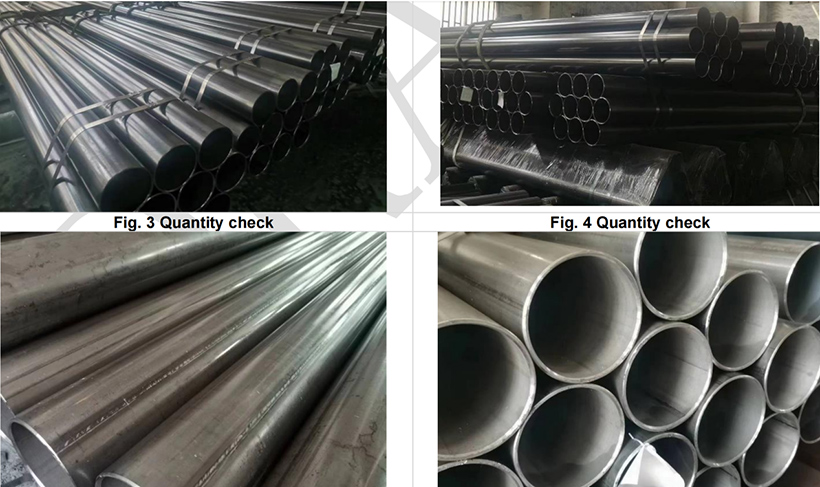

Qualitatis Moderatio

Inspectio Materiae Rudis, Analysis Chemica, Examen Mechanica, Inspectio Visualis, Examen Tensionis, Examen Dimensionis, Examen Flexionis, Examen Planificationis, Examen Impactus, Examen DWT, Examen NDT, Examen Hydrostaticum, Examen Duritudinis…..

Notatio, pictura ante traditionem.

Sarcina et Transportatio

Modus sarcinandi tuborum ferreorum purgationem, congregationem, involucrum, fasciculationem, firmationem, inscriptionem, palettationem (si opus est), receptacula, reponendum, obsignationem, transportationem, et disarcionem complectitur. Genera varia tuborum ferreorum et iuncturae cum variis modis sarcinandi. Hic processus comprehensivus efficit ut tubi ferrei transportentur et ad destinationem suam in optima condicione perveniant, ad usum destinatum parati.

Usus et Applicatio

Tubi ferrei quasi spina dorsalis modernae artis industrialis et civilis funguntur, amplam varietatem applicationum sustinentes quae ad progressionem societatum et oeconomiarum toto orbe conferunt.

Tubi et accessiones ferreae, quas Womic Steel producimus, late adhibitae sunt ad fistulas petrolei, gasii, cibustibilis et aquae, opera extra litus/terra, portuum maritimorum constructionis et aedificationis, dragationem, ferrum structurale, palos et pontium constructionis, necnon tubos ferreos accurati ad productionem cylindrorum transportatorum, et cetera...