Descriptio Producti

Tubi ferrei spirales, etiam tubi helicales submersi arcu conglutinati (HSAW) appellati, sunt genus tubi ferrei quod processu fabricationis singulari et proprietatibus structuralibus insignitur. Hi tubi late in variis industriis propter firmitatem, durabilitatem, et adaptabilitatem adhibentur. Hic est descriptio accurata tuborum ferreorum spiralium:

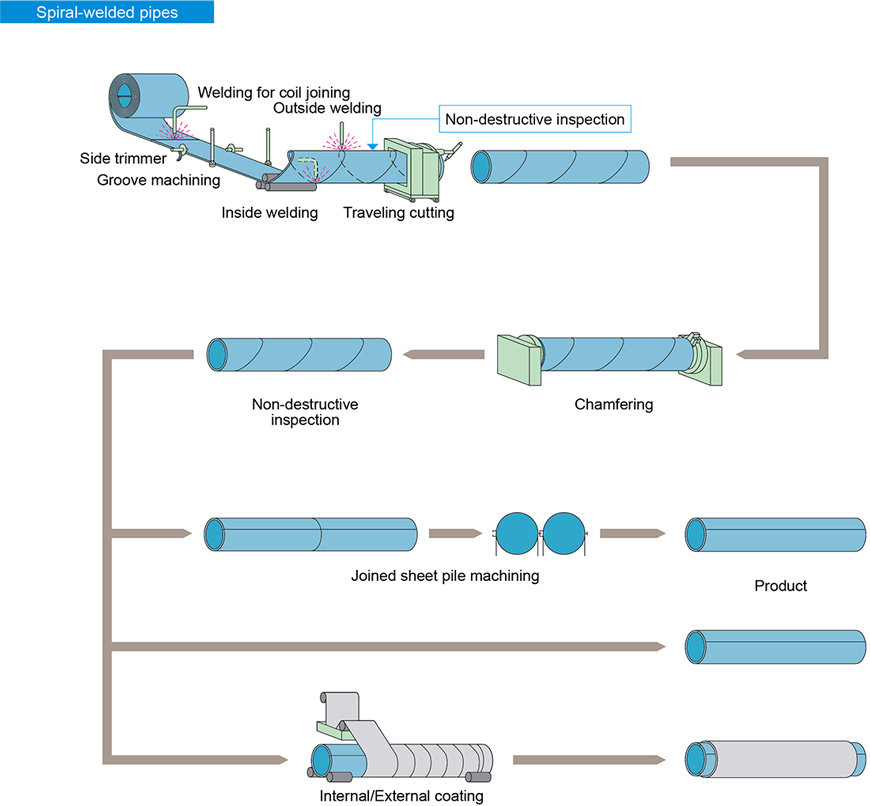

Processus Fabricationis:Tubi ferrei spirales per processum singularem producuntur, qui usum spiralis laminae ferreae implicat. Lamina explicatur et in formam spiralem formatur, deinde per artem sudurae arcus submersi (SAW) conglutinatur. Hic processus suturam helicalem continuam per longitudinem tubi efficit.

Designatio Structuralis:Sutura helicalis tuborum ferreorum spiralium robur naturale praebet, quo fit ut onera et pressiones magnas sustinere possint. Haec forma distributionem uniformem tensionis praestat et facultatem tubi resistendi flexionis et deformationi auget.

Magnitudinis Intervallum:Tubi ferrei spirales in amplam varietatem diametrorum (usque ad 120 pollices) et crassitudinum praebent, flexibilitatem in variis applicationibus praebentes. Saepe in maioribus diametris praesto sunt, comparati cum aliis generibus tuborum.

Applicationes:Tubi ferrei spirales in variis industriis, ut in oleo et gaso, aquae subministratione, constructione, agricultura, et evolutione infrastructurarum, adhibentur. Tam supra terram quam subterraneis usibus apti sunt.

Resistentia corrosionis:Ad diuturnitatem augendam, tubi ferrei spirales saepe curationibus anticorrosioni subeunt. Hae curationes includunt tunicas internas et externas, ut epoxy, polyethylene, et zincum, quae tubos ab elementis externis et substantiis corrosivis protegunt.

Commoda:Tubi ferrei spirales plura commoda offerunt, inter quae magna capacitas oneris ferendi, sumptus moderati pro tubis magni diametri, facilitas institutionis, et resistentia deformationi. Designatio helicalis etiam ad efficientem exhauritionem aquam adiuvat.

LongitudinalisVSSpirale:Tubi ferrei spirales a tubis longitudinaliter conglutinatis distinguuntur per processum fabricationis. Dum tubi longitudinales per longitudinem tubi formantur et conglutinantur, tubi spirales suturam helicalem in fabricatione habent.

Qualitatis Moderatio:Processus fabricationis et qualitatis moderationis maximi momenti sunt in productione tuborum ferreorum spiralium fidorum. Parametri soldadurae, geometria tuborum, et modi probationis diligenter observantur ut normas et specificationes industriales observentur.

Normae et Specificationes:Tubi ferrei spirales secundum normas internationales et industriales, ut API 5L, ASTM, EN, et alias, fabricantur. Hae normae proprietates materiarum, modos fabricationis, et requisita probationum definiunt.

Summa summarum, tubi ferrei spirales solutionem versatilem et durabilem variis industriis praebent. Singularis processus fabricationis, robur intrinsecum, et disponibilitas variis magnitudinibus ad usum late diffusum in infrastructura, transportatione, energia, constructione portuum et pluribus conferunt. Recta selectio, qualitas inspecta, et mensurae tutelae contra corrosionem partes cruciales agunt in diuturna efficacia tuborum ferreorum spiralium confirmanda.

Specificationes

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| ASTM A252: GR.1, GR.2, GR.3 |

| EN 10219-1: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A53/A53M: GR.A, GR.B |

| EN 10217: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| DIN 2458: St37.0, St44.0, St52.0 |

| AS/NZS 1163: Gradus C250, Gradus C350, Gradus C450 |

| GB/T 9711: L175, L210, L245, L290, L320, L360, L390, L415, L450, L485. |

| ASTMA671: CA55/CB70/CC65, CB60/CB65/CB70/CC60/CC70, CD70/CE55/CE65/CF65/CF70, CF66/CF71/CF72/CF73, CG100/CH100/CI100/CJ100 |

| Diameter (mm) | Crassitudo parietis (mm) | |||||||||||||||||||

| 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | |

| 219.1 | ● | ● | ● | ● | ||||||||||||||||

| 273 | ● | ● | ● | ● | ● | |||||||||||||||

| 323.9 | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| 325 | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| 355.6 | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| 377 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 406.4 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 426 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 457 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 478 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 508 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 529 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| DCXXX | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||

| DCCXI | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| DCCXX | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| DCCCXIII | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||

| DCCCXX | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||

| 920 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 1020 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 1220 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 1420 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 1620 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||

| MDCCCXX | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| Anno MMXX | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 2220 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 2500 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 2540 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| tria milia | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||

Tolerantia Diametri Externi et Crassitudinis Muri

| Norma | Tolerantia Corporis Tubi | Tolerantia Finis Tubi | Tolerantia Crassitudinis Muri | |||

| Diameter Externus | Tolerantia | Diameter Externus | Tolerantia | |||

| GB/T3091 | Diametros exterior ≤ 48.3 mm | ≤±0.5 | Diametros exterior ≤ 48.3 mm | - | ≤±10% | |

| 48.3 | ≤±1.0% | 48.3 | - | |||

| 273.1 | ≤±0.75% | 273.1 | -0.8~+2.4 | |||

| Diameter externus > 508 mm | ≤±1.0% | Diameter externus > 508 mm | -0.8~+3.2 | |||

| GB/T9711.1 | Diametros exterior ≤ 48.3 mm | -0.79~+0.41 | - | - | OD≤73 | -12.5%~+20% |

| 60.3 | ≤±0.75% | Diametros exterior ≤ 273.1 mm | -0.4~+1.59 | 88.9≤OD≤457 | -12.5%~+15% | |

| 508 | ≤±1.0% | OD ≥323.9 | -0.79~+2.38 | OD≥508 | -10.0%~+17.5% | |

| Diameter externus (OD) > 941mm | ≤±1.0% | - | - | - | - | |

| GB/T9711.2 | sexaginta | ±0.75%D ~ ±3mm | sexaginta | ±0.5%D ~ ±1.6mm | 4mm | ±12.5%T ~ ±15.0%T |

| DCX | ±0.5%D ~ ±4mm | DCX | ±0.5%D ~ ±1.6mm | Pondus ≥ 25mm | -3.00mm ~ +3.75mm | |

| Diameter externus (OD) > 1430mm | - | Diameter externus (OD) > 1430mm | - | - | -10.0%~+17.5% | |

| SY/T5037 | Diametros exterior <508mm | ≤±0.75% | Diametros exterior <508mm | ≤±0.75% | Diametros exterior <508mm | ≤±12.5% |

| Diametros exterior ≥ 508 mm | ≤±1.00% | Diametros exterior ≥ 508 mm | ≤±0.50% | Diametros exterior ≥ 508 mm | ≤±10.0% | |

| API 5L PSL1/PSL2 | OD<60.3 | -0.8mm ~ +0.4mm | OD≤168.3 | -0.4mm ~ +1.6mm | Pondus ≤ 5.0 | ≤±0.5 |

| 60.3≤OD≤168.3 | ≤±0.75% | 168.3 | ≤±1.6mm | 5.0 | ≤±0.1T | |

| 168.3 | ≤±0.75% | DCX | ≤±1.6mm | T≥15.0 | ≤±1.5 | |

| DCX | ≤±4.0mm | OD>1422 | - | - | - | |

| OD>1422 | - | - | - | - | - | |

| API 5CT | OD<114.3 | ≤±0.79mm | OD<114.3 | ≤±0.79mm | ≤-12.5% | |

| OD ≥114.3 | -0.5% ~ 1.0% | OD ≥114.3 | -0.5% ~ 1.0% | ≤-12.5% | ||

| ASTM A53 | ≤±1.0% | ≤±1.0% | ≤-12.5% | |||

| ASTM A252 | ≤±1.0% | ≤±1.0% | ≤-12.5% | |||

| DN mm | NB Uncia | OD mm | SCH40S mm | SCH5S mm | SCH10S mm | SCH10 mm | SCH20 mm | SCH40 mm | SCH60 mm | XS/80S mm | SCH80 mm | SCH100 mm | SCH120 mm | SCH140 mm | SCH160 mm | SCHXXS mm |

| 6 | 1/8" | 10.29 | 1.24 | 1.73 | 2.41 | |||||||||||

| 8 | 1/4" | 13.72 | 1.65 | 2.24 | 3.02 | |||||||||||

| 10 | 3/8" | 17.15 | 1.65 | 2.31 | 3.20 | |||||||||||

| 15 | Dimidium unciae | 21.34 | 2.77 | 1.65 | 2.11 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | ||||||

| 20 | Tres quartae unciae | 26.67 | 2.87 | 1.65 | 2.11 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | ||||||

| 25 | 1" | 33.40 | 3.38 | 1.65 | 2.77 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | ||||||

| 32 | Unciae quartae | 42.16 | 3.56 | 1.65 | 2.77 | 3.56 | 4.85 | 4.85 | 6.35 | 9.70 | ||||||

| 40 | Unciae unae et dimidiae | 48.26 | 3.68 | 1.65 | 2.77 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 | ||||||

| 50 | Duo" | 60.33 | 3.91 | 1.65 | 2.77 | 3.91 | 5.54 | 5.54 | 9.74 | 11.07 | ||||||

| 65 | Duae et dimidiae unciae | 73.03 | 5.16 | 2.11 | 3.05 | 5.16 | 7.01 | 7.01 | 9.53 | 14.02 | ||||||

| 80 | Tres" | 88.90 | 5.49 | 2.11 | 3.05 | 5.49 | 7.62 | 7.62 | 11.13 | 15.24 | ||||||

| 90 | Tres et dimidiae unciae | 101.60 | 5.74 | 2.11 | 3.05 | 5.74 | 8.08 | 8.08 | ||||||||

| centum | 4" | 114.30 | 6.02 | 2.11 | 3.05 | 6.02 | 8.56 | 8.56 | 11.12 | 13.49 | 17.12 | |||||

| 125 | Quinque" | 141.30 | 6.55 | 2.77 | 3.40 | 6.55 | 9.53 | 9.53 | 12.70 | 15.88 | 19.05 | |||||

| CL | Sex" | 168.27 | 7.11 | 2.77 | 3.40 | 7.11 | 10.97 | 10.97 | 14.27 | 18.26 | 21.95 | |||||

| ducenti | Octo" | 219.08 | 8.18 | 2.77 | 3.76 | 6.35 | 8.18 | 10.31 | 12.70 | 12.70 | 15.09 | 19.26 | 20.62 | XXIII.I | 22.23 | |

| 250 | Decem" | 273.05 | 9.27 | 3.40 | 4.19 | 6.35 | 9.27 | 12.70 | 12.70 | 15.09 | 19.26 | 21.44 | 25.40 | 28.58 | 25.40 | |

| trecenti | Duodecim" | 323.85 | 9.53 | 3.96 | 4.57 | 6.35 | 10.31 | 14.27 | 12.70 | 17.48 | 21.44 | 25.40 | 28.58 | 33.32 | 25.40 | |

| 350 | Quattuordecim" | 355.60 | 9.53 | 3.96 | 4.78 | 6.35 | 7.92 | 11.13 | 15.09 | 12.70 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | |

| quadringenti | XVI" | 406.40 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 12.70 | 16.66 | 12.70 | 21.44 | XXVI.XIX | 30.96 | 36.53 | 40.49 | |

| 450 | 18" | 457.20 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 14.27 | 19.05 | 12.70 | 23.83 | 29.36 | 34.93 | 39.67 | 45.24 | |

| quingenti | Viginti" | 508.00 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 15.09 | 20.62 | 12.70 | XXVI.XIX | 32.54 | 38.10 | 44.45 | 50.01 | |

| 550 | XXII" | 558.80 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 22.23 | 12.70 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | ||

| DC | XXIV" | 609.60 | 9.53 | 5.54 | 6.35 | 6.35 | 9.53 | 17.48 | 24.61 | 12.70 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | |

| DCCL | XXVI" | 660.40 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| DCC | 28" | 711.20 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| DCCCL | Triginta" | 762.00 | 9.53 | 6.35 | 7.92 | 7.92 | 12.70 | 12.70 | ||||||||

| DCCC | 32" | 812.80 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| DCCCL | XXXIV" | 863.60 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 900 | 36" | 914.40 | 9.53 | 7.92 | 12.70 | 19.05 | 12.70 | |||||||||

| DN 1000mm et supra Diametros crassitudines parietis tubi Maximum 25mm | ||||||||||||||||

Norma et Gradus

| Norma | Gradus Ferri |

| API 5L: Specificatio pro Tubo Lineari | GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| ASTM A252: Specificatio Standardis pro Palis Tuborum Chalybeorum Conglutinatis et Sinsuratis | Gradus Primus, Gradus Secundus, Gradus Tertius |

| EN 10219-1: Sectiones Cavae Structurales Frigidae et Soldatae ex Chalybe Non-Mixto et Grano Tenui | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: Sectiones Cavae Structurales Calido Perfectae ex Chalybe Non-Mixto et Grano Tenui | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A53/A53M: Tubus, Chalybeus, Niger et Calido Intinctus, Zinco Obductus, Soldatus et Sine Suturitate | GRADUS A, GRADUS B |

| EN 10217: Tubi Ferrei Conglutinati ad Usus Pressionis | P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| DIN 2458: Tubi et Tubi Ferrei Conglutinati | St37.0, St44.0, St52.0 |

| AS/NZS 1163: Norma Australiana/Novae Zelandiae pro Sectionibus Cavis Chalybis Structuralis Frigide Formatis | Gradus C250, Gradus C350, Gradus C450 |

| GB/T 9711: Industriae Petrolei et Gasis Naturalis - Tubus Ferreus pro Tubis | L175, L210, L245, L290, L320, L360, L390, L415, L450, L485 |

| AWWA C200: Tubus Aquaticus Ferreus 6 Pollices (150 mm) et Maior | Chalybs Carbonicus |

Processus Fabricationis

Qualitatis Moderatio

● Inspectio Materiae Crudae

● Analysis Chemica

● Examen Mechanicale

● Inspectio Visualis

● Dimensionum Inspectio

● Examen Flexionis

● Examen Impactus

● Examen Corrosionis Intergranularis

● Examen Non Destructivum (UT, MT, PT)

● Qualificatio Procedurae Soldandi

● Analysis Microstructurae

● Examen Expansionis et Applanationis

● Examen Duritiae

● Examinatio Pressionis

● Examen Metallographiae

● Examen Corrosionis

● Examen Currentis Turbinis

● Inspectio Picturae et Tegumentorum

● Recensio Documentorum

Usus et Applicatio

Tubi ferrei spirales propter suas proprietates et commoda singularia versatiles sunt et in variis industriis late adhibentur. Formantur per helicem ferream laminarum conglutinationem ut tubus cum continua sutura spirali creetur. Hic sunt nonnullae applicationes communes tuborum ferreorum spiralium:

● Transportatio Fluidorum: Hae fistulae aquam, oleum, et gas per longas distantias in fistulis efficaciter movent propter structuram sine suturis et magnam firmitatem.

● Petroleum et Gas: Necessaria industriis petrolei et gasi, petroleum crudum, gas naturale, et producta purificata transportant, necessitatibus explorationis et distributionis servientes.

● Pali figendi: Pali fundamentorum in operibus constructionis onera gravia in structuris ut aedificiis et pontibus sustinent.

● Usus Structuralis: In aedificandis structuris, columnis et fulcris adhibita, eorum firmitas ad stabilitatem structurae confert.

● Cuniculi et Drenagii: In systematibus aquariis adhibiti, resistentia corrosionis et interiora levia obstructionem prohibent et fluxum aquae augent.

● Tubi Mechanici: In fabricatione et agricultura, hi tubi solutiones robustas et sumptibus parcentes pro componentibus praebent.

● Maritima et Extra Littoralis: In condicionibus asperis, in fistulis submarinis, suggestis maritimis, et constructione portuum adhibentur.

● Fodinae: Materias et lutum in operationibus fodinarum difficilibus propter constructionem robustam transportant.

● Aquae Copia: Idonea fistulis magni diametri in systematibus aquariis, volumina aquae significantia efficaciter transportans.

● Systema Geothermica: In proiectis energiae geothermicae adhibita, translationem fluidorum calori resistentem inter receptacula et centrales electricas tractant.

Natura versatilis tuborum ferreorum spiralium, cum robore, firmitate, et adaptabilitate coniuncta, eos elementum essentiale per latam industriarum et applicationum varietatem facit.

Sarcina et Transportatio

Sarcina:

Processus sarcinandi tuborum ferreorum spiralium complures gradus clavis complectitur ut tubi satis protegantur durante transportatione et conservatione:

● Fasciculatio Tuborum: Tubi ferrei spirales saepe fasciculis, taeniis ferreis, aliisve modis firmis coniunguntur. Fasciculatio impedit ne singuli tubi intra involucrum moveantur aut moveantur.

● Protectio Extremitatis Tuborum: Opercula plastica vel tegumenta protectora in utroque extremo tuborum ponuntur ne extremitatibus tuborum et superficiei internae noceantur.

● Impermeabilitas: Tubi materiis impermeabilibus, ut laminis vel involucris plasticis, involvuntur, ut ab humiditate protegantur durante transportatione, praesertim in navigatione externa vel maritima.

● Impletio: Materiae impletionis additae, ut insertiones spumae vel materiae molliores, inter tubos vel in punctis vulnerabilibus addi possunt ad ictus et vibrationes absorbendas.

● Inscriptio: Quaeque fascicula informationibus magni momenti, inter quas specificationes tuborum, dimensiones, quantitas et destinatio, inscripta est. Hoc facilem identificationem et tractationem adiuvat.

Navigatio:

● Transportatio tuborum ferreorum spiralium diligentem consilium requirit ut tuta et efficax vectura fiat:

● Modus Vecturae: Electio modi vecturae (via, ferrivia, maritima, vel aerea) a factoribus ut distantia, urgentia, et accessibilitate ad locum destinatum pendet.

● Containerizatio: Tubi in receptacula navalia communia vel receptacula plana specialia onerari possunt. Containerizatio tubos ab elementis externis protegit et ambitum moderatum praebet.

● Firmatio: Tubi intra receptacula firmantur modis idoneis iuncturae, ut fulcris, obstructionibus, et vinculis. Hoc motum prohibet et periculum damni in itinere minuit.

● Documentatio: Documenta accurata, inter quae sunt facturae, indices sarcinandi, et manifesta vecturae, ad usus exonerationis vectigalium et vestigationis parantur.

● Assicuratio: Assicuratio mercium saepe comparatur ad damna vel damna potentialia in itinere tegenda.

● Monitorium: Per totum processum vecturae, tubi per GPS et systemata vestigationis observari possunt ut in recta via et tempore sint.

● Vectigalia Exoneratio: Documenta apta praebentur ut vectigalia expedite exonerari possint ad portum destinationis vel ad limitem.

Conclusio:

Recta sarcinatio et vectura tuborum ferreorum spiralium necessaria est ad qualitatem et integritatem tuborum durante vectura conservandam. Optimas rationes industriales sequendo, efficitur ut tubi ad destinationem optima condicione perveniant, parati ad institutionem vel ulteriorem processum.