Descriptio Producti

Informationes Normae - ASME/ANSI B16.5 et B16.47 - Flanges Tuborum et Iuncturae Flangatae

Norma ASME B16.5 varias partes flangarum tuborum et iuncturarum flangatarum tractat, inter quas aestimationes pressionis et temperaturae, materiae, dimensiones, tolerantiae, notationes, probationes, et designationes aperturarum pro his componentibus. Haec norma flangas cum designationibus classium aestimatarum ab 150 ad 2500 includit, magnitudines ab NPS 1/2 usque ad NPS 24 tegens. Requisita in unitatibus metricis et Americanis praebet. Interest notare hanc normam ad flangas et iuncturas flangatas ex materiis fusis vel fusis factas limitari, inter quas flangas caecae et flangas specificas reducentes ex materiis fusis, fusis, vel laminaribus factas.

Pro flangibus tuborum et iuncturis flangatis maioribus quam 24" NPS, norma ASME/ANSI B16.47 referenda est.

Typi Flangarum Communium

● Flanges Labiles: Hae flanges vulgo in promptu sunt secundum ANSI Classes 150, 300, 600, 1500 et 2500 usque ad 24" NPS. "Super" extrema tubi vel iuncturae "labiles" imponuntur et in loco suo conglutinantur, ita ut suturae angulares et intra et extra flangem permittentur. Versiones reductionis adhibentur ad magnitudines linearum minuendas cum spatium limitatum est.

● Flanges Colli Sudabilis: Hae flanges molum longum et conicum distinctum et crassitudinis transitionem lenem habent, quae plenam penetrationem nexus sudabilis cum tubo vel aptatione praestant. In condicionibus severis adhibentur.

● Flanges Articulorum Superpositi: Cum extremo stipitis coniunctae, flanges articulorum super aptationem extremitatis stipitis immittuntur et per ferruminationem vel alias rationes connectuntur. Forma laxa facilem ordinationem permittit dum componitur et disiungitur.

● Flanges Supportantes: Hae flanges facie elevata carent et cum anulis supportantibus adhibentur, solutiones efficaces sumptibus pro conexionibus flangarum praebentes.

● Flanges Filetatae (Cochleatae): Perforatae ad diametra interna tuborum specifica congruentes, flanges filetatae machinantur cum filis tuborum conicis in latere averso, praesertim pro tubis minoris diametri.

● Flanges Sudurae Alveolatae: Flanges labiales similes, flanges sudurae alveolatae ad magnitudinem alveolorum tuborum accommodantur, ita ut sudura anguli in parte posteriori permittitur ad coniunctionem firmandam. Typice in tubis minoris diametri adhibentur.

● Flanges Caecae: Hae flanges nullum foramen centrale habent et ad claudendum vel obstruendum finem systematis tuborum adhibentur.

Haec sunt quaedam genera flangarum tuborum communia quae in variis applicationibus industrialibus et commercialibus adhibentur. Electio generis flangae a factoribus ut pressione, temperatura, et genere fluidi transportati, necnon requisitis specificis propositi, pendet. Recta selectio et installatio flangarum necessariae sunt ad operationem tutam et efficientem systematum tuborum.

Specificationes

| ASME B16.5: Chalybs Carbonicus, Chalybs Inoxidabilis, Chalybs Mixtus |

| EN 1092-1: Chalybs Carbonicus, Chalybs Inoxidabilis, Chalybs Mixtus |

| DIN 2501: Chalybs Carbonicus, Chalybs Inoxidabilis, Chalybs Mixtus |

| GOST 33259: Chalybs Carbonicus, Chalybs Inoxidabilis, Chalybs Mixtus |

| SABS 1123: Chalybs Carbonicus, Chalybs Inoxidabilis, Chalybs Mixtus |

Materiae flangarum

Flanges tubo et rostro apparatui conglutinantur. Proinde, ex sequentibus materiis fabricatur;

● Chalybs carbonicus

● Chalybs humilis mixturae

● Chalybs inoxidabilis

● Combinatio materiarum exoticarum (Stub) et aliarum materiarum substratarum

Index materiarum in fabricatione adhibitarum in ASME B16.5 et B16.47 tractatur.

● ASME B16.5 - Flanges Tuborum et Iuncturae Flangatae NPS ½" ad 24"

● ASME B16.47 - Flanges Ferreae Magni Diametri NPS 26" ad 60"

Gradus materiae fusae vulgo adhibiti sunt

● Chalybs Carbonicus: – ASTM A105, ASTM A350 LF1/2, ASTM A181

● Chalybs mixtus: – ASTM A182F1 /F2 /F5 /F7 /F9 /F11 /F12 /F22

● Chalybs Inoxidabilis: – ASTM A182F6 /F304 /F304L /F316 /F316L/ F321/F347/F348

Dimensiones Flanges Classis 150 Labendi

| Magnitudo in pollice | Magnitudo in mm | Diametros Exteriores | Flanga crassa. | Hub OD | Longitudo flangis | Diametrum RF | Altitudo RF | PCD | Foramen Socketi | Numerus Clavorum | Magnitudo clavi UNC | Longitudo Clavi Machinalis | Longitudo Clavi RF | Magnitudo Foraminis | Magnitudo Clavi ISO | Pondus in chiliogrammatibus |

|

|

| A | B | C | D | E | F | G | H |

|

|

|

|

|

|

|

| Dimidium | 15 | 90 | 9.6 | 30 | 14 | 34.9 | 2 | 60.3 | 22.2 | 4 | Dimidium | 50 | 55 | 5/8 | M14 | 0.8 |

| Tres quartae partes | 20 | centum | 11.2 | 38 | 14 | 42.9 | 2 | 69.9 | 27.7 | 4 | Dimidium | 50 | 65 | 5/8 | M14 | 0.9 |

| 1 | 25 | 110 | 12.7 | 49 | 16 | 50.8 | 2 | 79.4 | 34.5 | 4 | Dimidium | 55 | 65 | 5/8 | M14 | 0.9 |

| Quarta pars | 32 | 115 | 14.3 | 59 | 19 | 63.5 | 2 | 88.9 | 43.2 | 4 | Dimidium | 55 | 70 | 5/8 | M14 | 1.4 |

| 1 1/2 | 40 | 125 | 15.9 | 65 | 21 | 73 | 2 | 98.4 | 49.5 | 4 | Dimidium | 65 | 70 | 5/8 | M14 | 1.4 |

| 2 | 50 | CL | 17.5 | 78 | 24 | 92.1 | 2 | 120.7 | 61.9 | 4 | 5/8 | 70 | 85 | Tres quartae partes | M16 | 2.3 |

| Duo et dimidium | 65 | CLXXX | 20.7 | 90 | 27 | 104.8 | 2 | 139.7 | 74.6 | 4 | 5/8 | 75 | 90 | Tres quartae partes | M16 | 3.2 |

| 3 | 80 | 190 | 22.3 | 108 | 29 | 127 | 2 | 152.4 | 90.7 | 4 | 5/8 | 75 | 90 | Tres quartae partes | M16 | 3.7 |

| Tres et dimidium | 90 | 215 | 22.3 | 122 | 30 | 139.7 | 2 | 177.8 | 103.4 | 8 | 5/8 | 75 | 90 | Tres quartae partes | M16 | 5 |

| 4 | centum | 230 | 22.3 | 135 | 32 | 157.2 | 2 | 190.5 | 116.1 | 8 | 5/8 | 75 | 90 | Tres quartae partes | M16 | 5.9 |

| 5 | 125 | 255 | 22.3 | CLXIV | 35 | 185.7 | 2 | 215.9 | 143.8 | 8 | Tres quartae partes | 85 | 95 | VII/VIII | M20 | 6.8 |

| 6 | CL | 280 | 23.9 | 192 | 38 | 215.9 | 2 | 241.3 | 170.7 | 8 | Tres quartae partes | 85 | centum | VII/VIII | M20 | 8.6 |

| 8 | ducenti | 345 | 27 | 246 | 43 | 269.9 | 2 | 298.5 | 221.5 | 8 | Tres quartae partes | 90 | 110 | VII/VIII | M20 | 13.7 |

| 10 | 250 | 405 | 28.6 | CCCV | 48 | 323.8 | 2 | 362 | 276.2 | 12 | VII/VIII | centum | 115 | 1 | M24 | 19.5 |

| 12 | trecenti | 485 | 30.2 | 365 | 54 | 381 | 2 | 431.8 | 327 | 12 | VII/VIII | centum | CXX | 1 | M24 | 29 |

| 14 | 350 | 535 | 33.4 | quadringenti | 56 | 412.8 | 2 | 476.3 | 359.2 | 12 | 1 | 115 | 135 | 1 1/8 | M27 | 41 |

| 16 | quadringenti | 595 | 35 | 457 | 62 | 469.9 | 2 | 539.8 | 410.5 | 16 | 1 | 115 | 135 | 1 1/8 | M27 | 54 |

| 18 | 450 | DCXXXV | 38.1 | 505 | 67 | 533.4 | 2 | 577.9 | 461.8 | 16 | 1 1/8 | 125 | 145 | Quarta pars | M30 | 59 |

| 20 | quingenti | DCC | 41.3 | 559 | 71 | 584.2 | 2 | DCXXXV | 513.1 | 20 | 1 1/8 | 140 | CLX | Quarta pars | M30 | 75 |

| 24 | DC | DCCCXV | 46.1 | DCCLXIII | 81 | 692.2 | 2 | 749.3 | DCXVI | 20 | Quarta pars | CL | CLXX | 1 3/8 | M33 | centum |

Dimensiones Flangis Colli Soldabilis Classis 150

| Magnitudo in pollice | Magnitudo in mm | Diameter externus | Crassitudo flangis | Hub OD | Diametros Externus Colli Weld | Longitudo Colli Soldandi | Foramen | Diameter RF | Altitudo RF | PCD | Facies Soldaturae |

|

|

| A | B | C | D | E | F | G | H | I | J |

| Dimidium | 15 | 90 | 9.6 | 30 | 21.3 | 46 | Foramen colli soldadurae ex indice tuborum derivatur. | 34.9 | 2 | 60.3 | 1.6 |

| Tres quartae partes | 20 | centum | 11.2 | 38 | 26.7 | 51 | 42.9 | 2 | 69.9 | 1.6 | |

| 1 | 25 | 110 | 12.7 | 49 | 33.4 | 54 | 50.8 | 2 | 79.4 | 1.6 | |

| Quarta pars | 32 | 115 | 14.3 | 59 | 42.2 | 56 | 63.5 | 2 | 88.9 | 1.6 | |

| 1 1/2 | 40 | 125 | 15.9 | 65 | 48.3 | 60 | 73 | 2 | 98.4 | 1.6 | |

| 2 | 50 | CL | 17.5 | 78 | 60.3 | 62 | 92.1 | 2 | 120.7 | 1.6 | |

| Duo et dimidium | 65 | CLXXX | 20.7 | 90 | 73 | 68 | 104.8 | 2 | 139.7 | 1.6 | |

| 3 | 80 | 190 | 22.3 | 108 | 88.9 | 68 | 127 | 2 | 152.4 | 1.6 | |

| Tres et dimidium | 90 | 215 | 22.3 | 122 | 101.6 | 70 | 139.7 | 2 | 177.8 | 1.6 | |

| 4 | centum | 230 | 22.3 | 135 | 114.3 | 75 | 157.2 | 2 | 190.5 | 1.6 | |

| 5 | 125 | 255 | 22.3 | CLXIV | 141.3 | 87 | 185.7 | 2 | 215.9 | 1.6 | |

| 6 | CL | 280 | 23.9 | 192 | 168.3 | 87 | 215.9 | 2 | 241.3 | 1.6 | |

| 8 | ducenti | 345 | 27 | 246 | 219.1 | centum | 269.9 | 2 | 298.5 | 1.6 | |

| 10 | 250 | 405 | 28.6 | CCCV | 273 | centum | 323.8 | 2 | 362 | 1.6 | |

| 12 | trecenti | 485 | 30.2 | 365 | 323.8 | 113 | 381 | 2 | 431.8 | 1.6 | |

| 14 | 350 | 535 | 33.4 | quadringenti | 355.6 | 125 | 412.8 | 2 | 476.3 | 1.6 | |

| 16 | quadringenti | 595 | 35 | 457 | 406.4 | 125 | 469.9 | 2 | 539.8 | 1.6 | |

| 18 | 450 | DCXXXV | 38.1 | 505 | 457.2 | 138 | 533.4 | 2 | 577.9 | 1.6 | |

| 20 | quingenti | DCC | 41.3 | 559 | 508 | 143 | 584.2 | 2 | DCXXXV | 1.6 | |

| 24 | DC | DCCCXV | 46.1 | DCCLXIII | DCX | 151 | 692.2 | 2 | 749.3 | 1.6 |

Dimensiones Flangis Caecae Classis 150

| Magnitudo | Magnitudo | Exterior | Flanga | RF | RF | PCD | Numerus | Magnitudo Clavi | Pessulus Machinalis | Clavus RF | Magnitudo Foraminis | Clavus ISO | Pondus |

| A | B | C | D | E | |||||||||

| Dimidium | 15 | 90 | 9.6 | 34.9 | 2 | 60.3 | 4 | Dimidium | 50 | 55 | 5/8 | M14 | 0.9 |

| Tres quartae partes | 20 | centum | 11.2 | 42.9 | 2 | 69.9 | 4 | Dimidium | 50 | 65 | 5/8 | M14 | 0.9 |

| 1 | 25 | 110 | 12.7 | 50.8 | 2 | 79.4 | 4 | Dimidium | 55 | 65 | 5/8 | M14 | 0.9 |

| Quarta pars | 32 | 115 | 14.3 | 63.5 | 2 | 88.9 | 4 | Dimidium | 55 | 70 | 5/8 | M14 | 1.4 |

| 1 1/2 | 40 | 125 | 15.9 | 73 | 2 | 98.4 | 4 | Dimidium | 65 | 70 | 5/8 | M14 | 1.8 |

| 2 | 50 | CL | 17.5 | 92.1 | 2 | 120.7 | 4 | 5/8 | 70 | 85 | Tres quartae partes | M16 | 2.3 |

| Duo et dimidium | 65 | CLXXX | 20.7 | 104.8 | 2 | 139.7 | 4 | 5/8 | 75 | 90 | Tres quartae partes | M16 | 3.2 |

| 3 | 80 | 190 | 22.3 | 127 | 2 | 152.4 | 4 | 5/8 | 75 | 90 | Tres quartae partes | M16 | 4.1 |

| Tres et dimidium | 90 | 215 | 22.3 | 139.7 | 2 | 177.8 | 8 | 5/8 | 75 | 90 | Tres quartae partes | M16 | 5.9 |

| 4 | centum | 230 | 22.3 | 157.2 | 2 | 190.5 | 8 | 5/8 | 75 | 90 | Tres quartae partes | M16 | 7.7 |

| 5 | 125 | 255 | 22.3 | 185.7 | 2 | 215.9 | 8 | Tres quartae partes | 85 | 95 | VII/VIII | M20 | 9.1 |

| 6 | CL | 280 | 23.9 | 215.9 | 2 | 241.3 | 8 | Tres quartae partes | 85 | centum | VII/VIII | M20 | 11.8 |

| 8 | ducenti | 345 | 27 | 269.9 | 2 | 298.5 | 8 | Tres quartae partes | 90 | 110 | VII/VIII | M20 | 20.5 |

| 10 | 250 | 405 | 28.6 | 323.8 | 2 | 362 | 12 | VII/VIII | centum | 115 | 1 | M24 | 32 |

| 12 | trecenti | 485 | 30.2 | 381 | 2 | 431.8 | 12 | VII/VIII | centum | CXX | 1 | M24 | 50 |

| 14 | 350 | 535 | 33.4 | 412.8 | 2 | 476.3 | 12 | 1 | 115 | 135 | 1 1/8 | M27 | 64 |

| 16 | quadringenti | 595 | 35 | 469.9 | 2 | 539.8 | 16 | 1 | 115 | 135 | 1 1/8 | M27 | 82 |

| 18 | 450 | DCXXXV | 38.1 | 533.4 | 2 | 577.9 | 16 | 1 1/8 | 125 | 145 | Quarta pars | M30 | centum |

| 20 | quingenti | DCC | 41.3 | 584.2 | 2 | DCXXXV | 20 | 1 1/8 | 140 | CLX | Quarta pars | M30 | 130 |

| 24 | DC | DCCCXV | 46.1 | 692.2 | 2 | 749.3 | 20 | Quarta pars | CL | CLXX | 1 3/8 | M33 | 196 |

Norma et Gradus

| ASME B16.5: Flanges Tuborum et Iuncturae Flangatae | Materiae: Chalybs Carbonicus, Chalybs Inoxidabilis, Chalybs Mixtus |

| EN 1092-1: Flanges et earum iuncturae - Flanges circulares pro tubis, valvis, aptationibus et accessionibus, designatae PN - Pars 1: Flanges ferreae | Materiae: Chalybs Carbonicus, Chalybs Inoxidabilis, Chalybs Mixtus

|

| DIN 2501: Flanges et Articuli Superpositi | Materiae: Chalybs Carbonicus, Chalybs Inoxidabilis, Chalybs Mixtus |

| GOST 33259: Flanges pro Valvis, Iuncturis, et Tubis ad Pressionem usque ad PN 250 | Materiae: Chalybs Carbonicus, Chalybs Inoxidabilis, Chalybs Mixtus |

| SABS 1123: Flanges pro Tubis, Valvis, et Iuncturis | Materiae: Chalybs Carbonicus, Chalybs Inoxidabilis, Chalybs Mixtus |

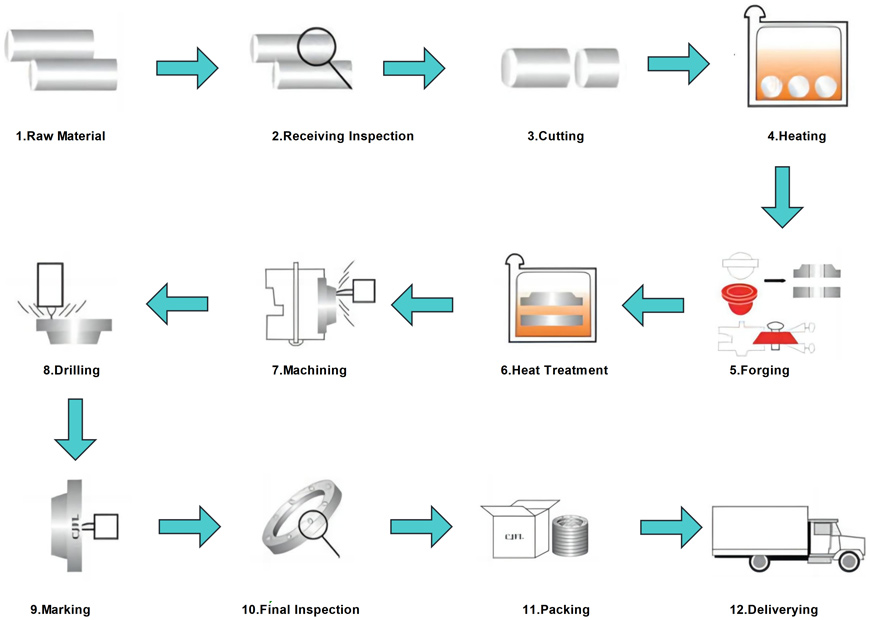

Processus Fabricationis

Qualitatis Moderatio

Inspectio Materiae Rudis, Analysis Chemica, Examen Mechanica, Inspectio Visualis, Inspectio Dimensionis, Examen Flexionis, Examen Planificationis, Examen Impactus, Examen DWT, Examen Non Destructivum (UT, MT, PT, X-Ray), Examen Duritiae, Examen Pressionis, Examen Effusionis Sedis, Examen Metallographiae, Examen Corrosionis, Examen Resistentiae Ignis, Examen Nebulae Salis, Examen Fluxus, Examen Momenti et Impulsionis, Inspectio Picturae et Tegumenti, Recensio Documentationis...

Usus et Applicatio

Flanges sunt partes industriales magni momenti ad tubos, valvas, apparatum et alia elementa tuborum coniungenda. Munus clavem agunt in coniungendis, sustentandis et obsignandis systematibus tuborum. Flanges ut elementa crucialia in variis applicationibus industrialibus funguntur, inter quas:

● Systema Tuborum

● Valvae

● Instrumenta

● Nexus

● Obsignatio

● Gubernatio Pressionis

Sarcina et Transportatio

Apud Womic Steel, intellegimus momentum involucri securi et vecturae certae cum ad perferendas fistulas nostras summae qualitatis ad limen tuum venit. Ecce conspectus rationum nostrarum involucri et vecturae ad referentiam tuam:

Involucrum:

Flanges nostrae tuborum diligenter involuuntur ut ad te in perfecta condicione perveniant, paratae ad necessitates tuas industriales vel commerciales. Processus noster involucri hos gradus principales comprehendit:

● Inspectio Qualitatis: Antequam involucrentur, omnes flanges diligenti inspectione qualitatis subeunt ut confirmentur an nostris severis normis functionis et integritatis satisfaciant.

● Tegumentum Protectivum: Pro genere materiae et applicationis, flanges nostrae tegumento protectivo uti possunt ad corrosionem et damnum durante transportatione prohibendum.

● Fasciculatio Secura: Flanges secure inter se conglutinantur, ita ut per totum processum translationis stabiles et protectae maneant.

● Inscriptiones et Documentatio: Quaeque sarcina clare inscripta est informationibus necessariis, inter quas specificationes producti, quantitas, et quaslibet instructiones speciales tractationis. Documentatio pertinentis, ut certificata obsequii, etiam includitur.

● Involucrum Speciale: Petitiones involucrorum specialium secundum necessitates tuas singulares accommodare possumus, curantes ut flanges tuae prorsus prout opus est praeparentur.

Navigatio:

Cum sociis vecturae probatis collaboramus ut certam et opportunam traditionem ad destinationem a te designatam praestemus. Turma nostra logistica vias vecturae optimizat ut tempora transitus quam minima sint et periculum morae reducat. Pro vecturis internationalibus, omnia documenta necessaria et obsequium consuetudinarium curamus ut expeditam exonerationem consuetudinariam faciliorem reddamus. Optiones vecturae flexibiles offerimus, inter quas vecturam acceleratam pro necessitatibus urgentibus.